Top Quality Machine Used for Sale | Affordable Machinery

Looking for cost-efficient equipment for your industrial needs? Discover our guide on used CNC vertical machining centers, milling machines, and the machine used CNC lathes. Find out how to choose the right machine and boost your productivity while saving costs.

Key Takeaways

-

The inventory of used machinery includes a variety of essential machine tools, such as CNC vertical machining centers, milling machines, and CNC lathes, offering buyers diverse options to enhance productivity while managing costs.

-

Key considerations for purchasing used machinery encompass evaluating machine condition, reviewing maintenance history, and aligning equipment capabilities with production requirements to avoid costly repairs and optimize operational efficiency.

-

Regular maintenance practices, including lubrication, cleaning, and inspections, are vital for extending the lifespan and performance of used machinery, ensuring continued productivity and reliability.

Top Used Machines Available

The inventory of used machinery spans a wide array of machine tools tailored for various industrial sectors. From CNC vertical machining centers to milling machines and CNC lathes, buyers can find manufacturing equipment and metalworking equipment that meets their specific needs and budget. Knowing the specifications and applications of these machines helps in making the right choice for your production processes.

Significant savings on used machines can boost your operational efficiency and productivity while keeping costs low.

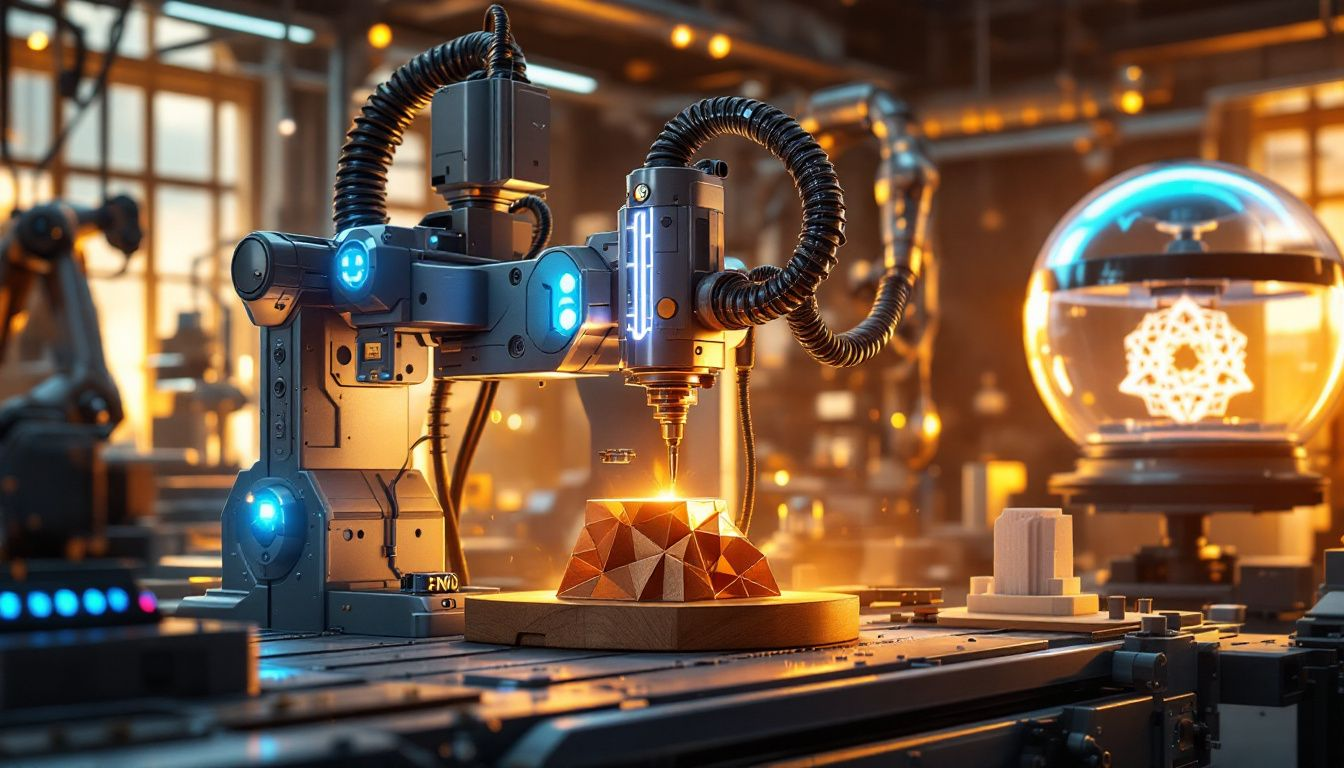

CNC Vertical Machining Centers

CNC vertical machining center are a cornerstone in many manufacturing facilities, known for their ability to perform complex cuts with high precision. These used CNC machines typically feature a vertically oriented spindle, which allows tools to cut directly down onto the workpiece, making them ideal for fabricating equipment, CNC machine tools, and metalworking tasks.

With specifications varying widely, including spindle speeds and axis movements, these centers can weigh between 1,000 to 35,000 pounds, catering to diverse operational needs.

Milling Machines

Milling machines are versatile tools in the realm of machine tools. Available in various brands known for their precision and reliability, these machines can perform a range of operations such as cutting, drilling, and threading. The cost of used milling machines varies significantly based on brand, model, age, and condition, with advanced models generally fetching higher prices.

This versatility and range of options make milling machines a valuable addition to any manufacturing setup.

CNC Lathes

CNC lathes are integral to industries that require precise shaping of cylindrical parts. Equipped with features like programmable controls, multi-axis machining capabilities, and automatic tool changers, these machines are designed for efficiency and precision.

Evaluating the condition of a used CNC lathe is important as it directly affects performance and longevity. Signs of wear, rust, and operational history should be meticulously evaluated to ensure a reliable purchase.

Key Considerations When Buying Used Machinery

When venturing into the purchase of used machinery, several key considerations must be kept in mind to ensure a wise investment. Evaluating the overall condition of the machinery, understanding its maintenance history, and aligning its capabilities with your production requirements are critical steps.

These factors help in avoiding costly repairs and ensuring that the machinery complements your operational needs, thereby enhancing productivity and efficiency.

Machine Condition

Evaluating the condition of used machinery involves a thorough inspection of various factors such as hours of operation, previous repairs, and visible damage like rust or dents. Routine inspections focused on wear can help identify issues before they lead to equipment failure.

Verifying that the machine fits your production needs and performing technical audits can greatly enhance the success of your purchase.

Maintenance History

Reviewing the maintenance history of used machinery is vital to understanding its reliability and performance. Requesting service logs and maintenance records helps determine the level of care the machine has received, which can be indicative of its future performance.

Proper documentation and thorough inspections are essential steps for successful transactions in the used machinery sector.

Production Requirements

Aligning the capabilities of the machinery with your production requirements is essential for maintaining efficiency and productivity. CNC vertical machining centers, for instance, are designed for precision machining of complex parts and can handle multiple operations like milling and drilling, making them popular in various manufacturing sectors.

Frequent calibration ensures these machines operate within specified tolerances, maintaining product quality and minimizing production errors.

Safe Shipping of Used Machinery

Safely transporting used machinery prevents damage and ensures it arrives in optimal condition. This process involves careful logistics planning and execution, including coordinating shipping logistics and ensuring compliance with regulations.

Proper handling and securing methods during transport safeguard the machinery against potential losses and damages.

Hiring Experienced Transport Services

Hiring experienced transport services ensures that your used machinery is handled by experts who understand its unique requirements. Professional transport services offer end-to-end logistics solutions, covering everything from loading to delivery, and prioritize safety and compliance with regulatory standards.

This minimizes the risk of damage or accidents during transit, ensuring that your equipment arrives safely and on time.

Securing and Protecting Equipment

Properly securing and protecting machinery during shipping is essential to prevent damage. Using methods like chains or straps can prevent movement and damage during transit. Additionally, covering machinery with protective materials can protect it from debris and moisture, ensuring it arrives in the best possible condition.

Skilled transport services can enhance the safety and efficiency of moving heavy machinery.

Regular Maintenance for Optimal Performance

Regular maintenance is crucial for maximizing the lifespan and efficiency of used machinery. This involves routine tasks such as:

-

lubrication

-

cleaning

-

inspection for wear

-

calibration

Following the manufacturer’s guidelines for maintenance tasks and keeping comprehensive records can help in budgeting for future repairs and replacements, ensuring that the machinery remains in optimal condition.

Lubrication and Cleaning

Regular lubrication and cleaning are essential for preventing friction and wear on moving parts of machinery. Proper lubrication reduces friction, helping to maintain equipment at optimal operating temperatures and ensuring efficient operation.

This simple yet effective maintenance task can extend the lifespan of your machinery and prevent costly breakdowns.

Inspection for Wear

Routine inspections are essential for identifying signs of wear and tear on machinery. This includes checking for visible wear, unusual noises, and operational anomalies. Testing the machinery during inspection can reveal performance issues and help in planning necessary repairs.

Regular inspections help maintain the performance and reliability of used machinery, ensuring it operates smoothly.

Calibration and Adjustments

Regular calibration of machinery is crucial for ensuring accuracy in operations, thus minimizing errors and maximizing productivity. Calibration checks should be performed at regular intervals or based on the frequency of machine use. Common adjustments include alignment, speed calibration, and checking operational parameters to ensure they meet specifications.

These adjustments help in fine-tuning the tooling machinery to adapt to specific production requirements over time.

Selling Your Used Machinery

Selling used machinery can be a hassle-free process if approached correctly. Ensuring payment before the machine leaves your factory and utilizing effective advertising strategies can attract potential buyers.

The selling process often includes promotions, visits, and legal documents to ensure a smooth transaction. By understanding the market and leveraging free promotion tools, you can maximize your chances of successfully selling your used machinery.

Free Promotion

Utilizing free promotion tools can significantly boost your outreach to potential buyers of used machinery. Platforms like Surplus Record allow for low-cost advertising of surplus industrial assets, and combining these platforms with a strong network of contacts can enhance your chances of finding a buyer.

Free promotion tools are an effective way to maximize your chances of successfully selling used machinery without incurring high advertising costs.

Risk Management

Selling used machinery involves certain risks that need to be managed effectively. Time pressure can complicate the selling process, as there is no definite timeline for completing sales. Additionally, personal liability is a significant risk during private sales if potential buyers are injured on your property.

Recognizing these risks and taking appropriate measures to mitigate them ensures a smoother selling process.

Online Marketplaces

Selling used machinery online is a strategic way to reach a wider audience and maximize the exposure of your equipment. Utilizing free promotion tools such as social media and online listings can significantly expand the reach of your offerings.

Implementing strategies to minimize risks, such as accurate descriptions and transparent communication, is essential when selling online. Understanding the process and target market can enhance the effectiveness of your online sales.

Trade Shows and Industry Events

Trade shows provide a unique platform for exploring new and used machinery options, fostering business relationships, and staying updated on industry trends. These events offer valuable insights and access to the best deals on used machinery.

They are also an excellent opportunity to network with key decision-makers and industry experts, making them an integral part of the machinery investment process.

Upcoming Events

Notable trade shows for purchasing used machinery are scheduled globally throughout the year, providing excellent opportunities to explore various types of machinery. For instance, the International Manufacturing Technology Show (IMTS) will be held from September 9 to 14, 2024, in Chicago, IL, showcasing a range of industrial equipment.

Similarly, the New England Farm Show, scheduled for February 20-22, 2025, focuses on agricultural machinery. Attending these events offers valuable insights and access to some of the best deals on used machinery.

Networking Opportunities

Manufacturing trade shows bring together key decision-makers, enabling businesses to build networks and connect with potential buyers. These events provide an excellent platform for making valuable industry connections and finding machinery deals.

Networking at trade shows can significantly enhance your market presence and open up new opportunities for business growth.

Personalized Assistance

Trade shows offer valuable platforms for personalized assistance in machinery investment, connecting buyers with sellers and industry experts. Many upcoming events include exhibitions, workshops, and sessions focusing on the latest machinery technologies.

Personalized assistance from trade shows leads to informed decisions and potentially better deals in machinery investments, making these events integral to the buying process.

Latest News and Updates

The used machinery market is evolving with digital platforms, making transactions more accessible and efficient. AI applications are increasingly being used to aid sellers in determining the value of their machines and optimal selling times.

Trade shows continue to play a significant role in connecting buyers and sellers, fostering market trends and developments. These platforms not only provide a space for building relationships but also for sharing insights on the latest machinery technologies.

Success Stories

Successful machinery sales not only benefit sellers financially but also contribute to a sustainable ecosystem within the industry. For example, farmers who strategically sell their machinery often realize significant returns on their investments when done at the right time. These success stories highlight the importance of timing and market knowledge in maximizing returns.

Additionally, creating a network of support by assisting buyers in operating equipment can enhance value for both parties.

Industry Trends

Trade shows play a critical role in connecting buyers and sellers in the used machinery industry, fostering market trends and developments. For instance, international plastics and beverage trade shows are on the agenda for MachinePoint in 2023, highlighting the ongoing trends in these sectors.

Staying updated on industry trends and attending relevant trade shows can provide valuable insights into market dynamics and help businesses stay competitive.

Expert Opinions

Experts stress assessing the machine’s condition before making a decision, including looking for signs of wear and tear. Knowing the maintenance history of used machinery can be crucial in determining the reliability of the equipment. Experts also recommend verifying that the machine meets specific production requirements to ensure it fits your manufacturing needs.

Leveraging online marketplaces and trade shows can attract more potential buyers for used machinery, leading to successful transactions.

Comprehensive Services for Used Machinery

A variety of services are designed to support both the purchase and sale of used machinery, ensuring a seamless transaction. These services include engineering, refurbishing, appraisals, and international transport. Provided by a team of experts specializing in various aspects of used machinery, these comprehensive services aim to enhance the operational efficiency and value of the machinery.

Engineering and Refurbishing

Engineering support is crucial in optimizing machinery performance to meet production goals. Refurbishing services are essential for updating machinery components, enhancing their efficiency and effectiveness.

By combining engineering support and refurbishing services, you can significantly enhance machine performance and extend its useful life, ensuring that your machinery continues to meet your operational needs.

Appraisals and Valuations

Professional appraisals accurately assess the market value of used machinery. These appraisals take into account factors like condition and specifications, ensuring a fair market value. Qualified experts conduct detailed appraisals, providing comprehensive reports that include methodologies and itemized asset lists, adhering to professional appraisal standards.

These appraisals are critical for various situations like financing, leasing, and litigation.

Transport and Logistics

International equipment transport services are provided to facilitate the movement of machinery across borders. These logistics solutions are crucial for ensuring the safe and timely movement of used machinery, protecting against potential losses and damages.

Leveraging professional transport and logistics services ensures your machinery arrives at its destination in optimal condition, regardless of location.

Summary

Navigating the used machinery market requires a strategic approach and careful consideration of various factors. From understanding the different types of available machines to evaluating their condition, reviewing maintenance history, and ensuring they meet production requirements, each step is crucial for making an informed purchase. Additionally, safe shipping practices, regular maintenance, and leveraging trade shows and online platforms can enhance your buying and selling experience. By utilizing comprehensive services like engineering, refurbishing, appraisals, and logistics, you can maximize the value and performance of your used machinery. Embrace these insights and take confident steps toward optimizing your industrial operations.

Frequently Asked Questions

What types of used machinery are commonly available?

Commonly available types of used machinery include CNC vertical machining centers, milling machines, and CNC lathes, each offering various specifications to address specific operational requirements.

How can I ensure the condition of used machinery before purchasing?

To ensure the condition of used machinery before purchasing, thoroughly inspect for visible damage, check the hours of operation, and review maintenance records. Additionally, consider conducting technical audits to confirm quality.

Why is maintenance history important when buying used machinery?

Maintenance history is crucial when purchasing used machinery as it reflects the reliability and care the equipment has received, directly influencing its future performance and longevity. Understanding this history helps buyers make informed decisions and avoid potential costly repairs.

What are the benefits of attending trade shows for used machinery?

Attending trade shows for used machinery provides valuable opportunities to explore a range of options, network with industry experts, and gain personalized assistance, ultimately facilitating informed purchasing decisions and favorable deals.

How can I safely ship used machinery?

To safely ship used machinery, it is essential to hire experienced transport services and employ proper securing methods while protecting the machinery with suitable materials. This approach ensures the machinery's safety during transit.