Top Manufacturers of Machinery: Leading the Industry

Are you looking for the top manufacturers of machinery to meet your business needs? This article features leading companies in key sectors like construction, agriculture, and industrial machinery. Explore their innovative products, technologies, and what makes them industry leaders.

Key Takeaways

- Top manufacturers in the machinery industry, including Caterpillar, Komatsu, and John Deere, lead through innovation, extensive product offerings, and a commitment to sustainability.

- Machinery manufacturers face significant challenges such as supply chain disruptions, technological advancements, and regulatory compliance that impact efficiency and sustainability.

- Technological trends like automation, IoT, and sustainable practices are reshaping the future of machinery manufacturing, driving companies to adapt and innovate in response to market demands.

Leading Manufacturers in the Construction Equipment Sector

The construction equipment sector forms the backbone of modern infrastructure development. Leading manufacturers set the bar for quality and innovation, continually advancing their technologies to meet the rigorous demands of construction projects globally.

Among the top players are Caterpillar, Komatsu, and Volvo Construction Equipment, each contributing significantly to the market through their extensive product offerings and groundbreaking innovations.

Caterpillar

Caterpillar, the world’s largest construction equipment manufacturer, exemplifies reliability and innovation. Its extensive product lineup includes excavators, wheeled loaders, skid steer loaders, motor graders, backhoe loaders, and hauling trucks, covering a wide range of construction needs. Caterpillar’s emphasis on customer connection and solutions has cemented its top position.

From heavy-duty excavation to precision grading, Caterpillar’s machines deliver performance and durability.

Komatsu

Komatsu, another giant in the construction machinery sector, is renowned for its innovative products and significant market presence. With reported sales of US$19.9 billion, Komatsu exemplifies the impact of technological advancements on company success. Its machinery, spanning a wide range of construction equipment, is known for reliability and cutting-edge features.

Komatsu’s influence extends globally, serving industries from construction to mining, and continually setting new benchmarks for equipment manufacturers.

Volvo Construction Equipment

Volvo Construction Equipment is a key player in the OEM market, known for its commitment to sustainability and technological innovation. The company’s focus on electric equipment and the integration of advanced technologies has set it apart in the construction machinery market.

By enhancing performance while ensuring environmental responsibility, Volvo is not only shaping the present but also paving the way for a greener future in construction.

Pioneers in Agricultural Machinery Manufacturing

The agricultural machinery sector is vital for modern farming, with leading manufacturers driving efficiency and innovation to meet market demands. Companies like John Deere, Case IH, and AGCO Corporation are at the forefront, offering advanced machinery that transforms agricultural practices.

These pioneers are not only enhancing productivity but also addressing the challenges of sustainability and technological integration in agriculture.

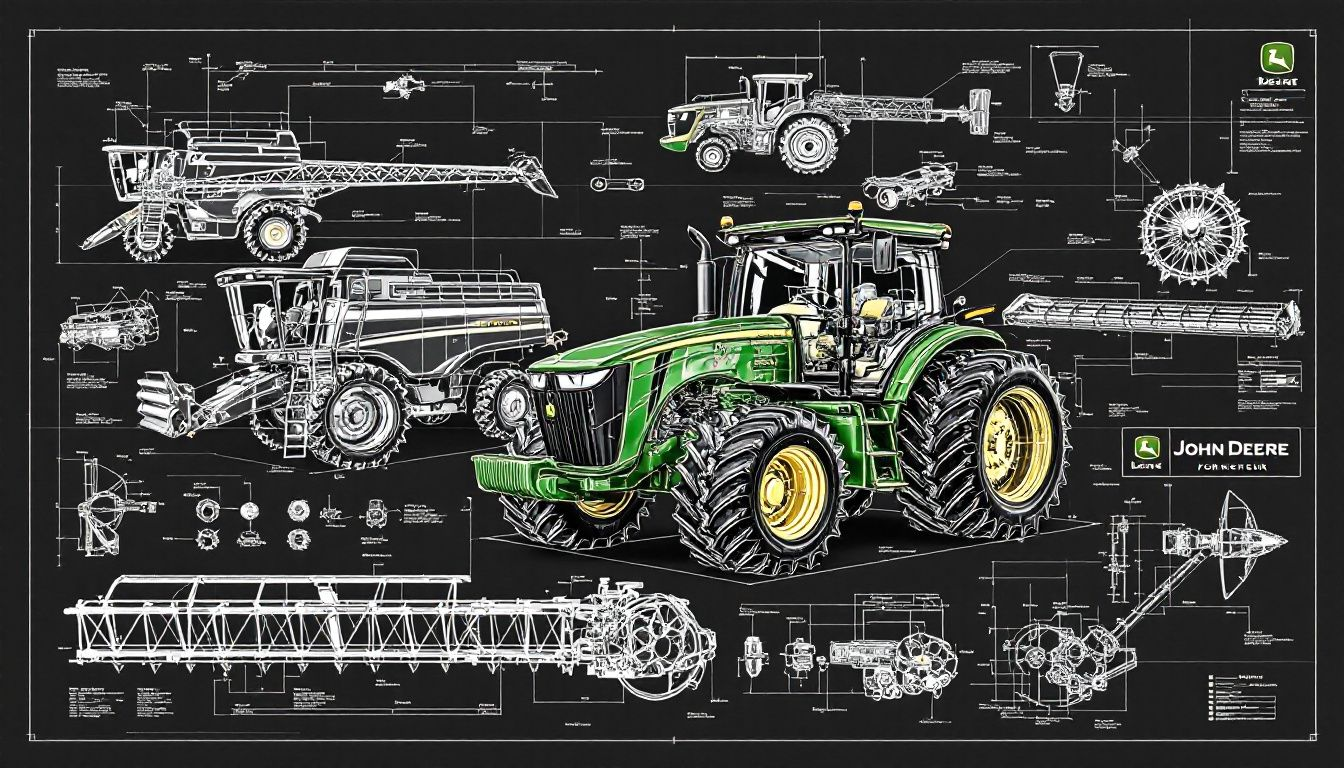

John Deere

Headquartered in Moline, Illinois, John Deere is a powerhouse in the agricultural machinery industry. With sales of US$11.3 billion, the company has made significant strides, including acquiring the Wirtgen Group to broaden its product range.

John Deere’s tractors and sensor-integrated machinery are especially popular in emerging markets like India and China, where government subsidies drive the modernization of farming. This focus on innovation and market expansion underscores John Deere’s leading industry position.

Case IH

Case IH utilizes Advanced Farming Systems (AFS) technology to boost productivity and efficiency in agriculture. Its Agronomic Design optimizes tools for High-Efficiency Farming, fine-tuning every detail for maximum output.

The introduction of Selective Catalytic Reduction technology further aids in managing fuel costs, positioning Case IH as a leader in innovative agricultural solutions.

AGCO Corporation

AGCO Corporation provides a diverse range of agricultural equipment that significantly enhances farming practices globally. Its focus on emerging markets underscores its strategy to meet local demand and expand its global presence. Continuous improvements in efficiency and productivity keep AGCO as a key player in the agricultural machinery sector.

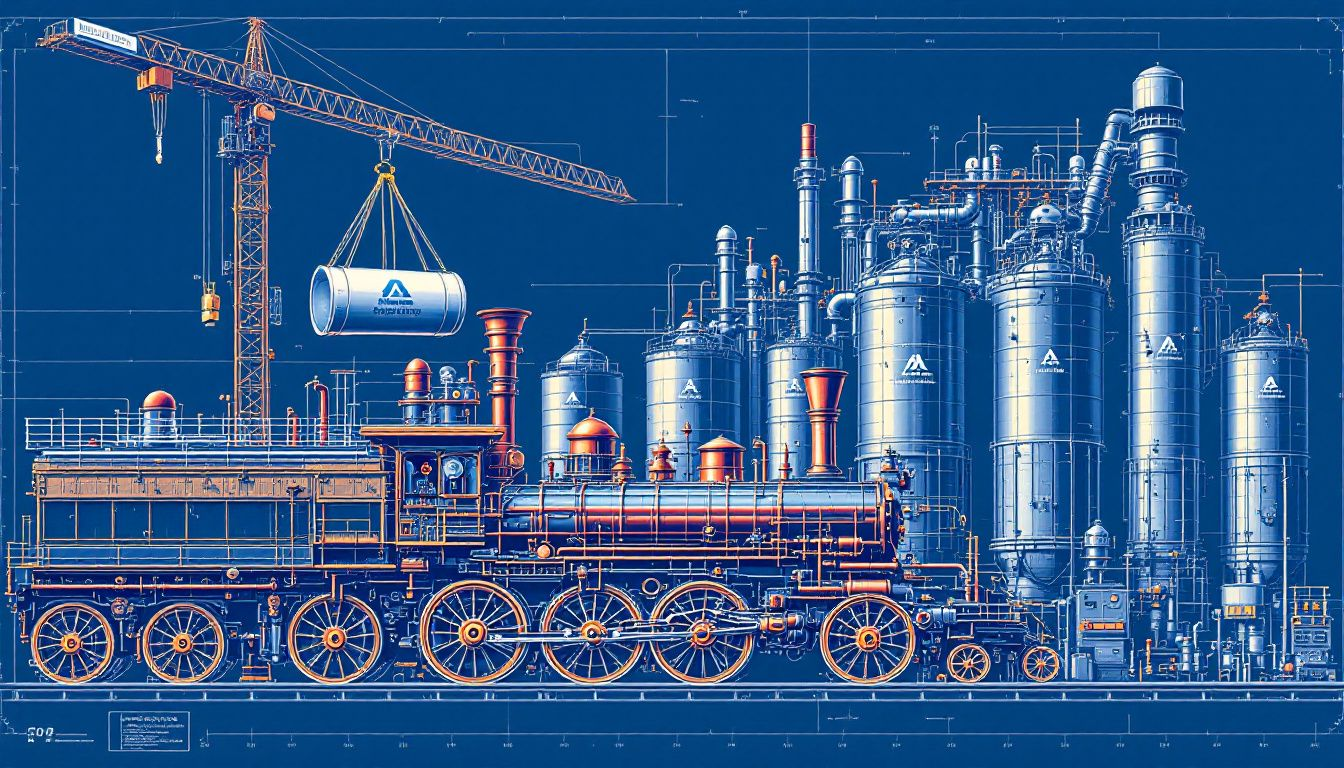

Industrial Machinery Giants

The industrial machinery sector is a critical component of the global economy, with giants like General Electric, Siemens, and Hitachi leading the way. These companies are known for their advanced technologies and innovative steel solutions that enhance efficiency and productivity across various industries in the world.

The U.S. industrial machinery sector alone is valued at approximately $223.6 billion, employing around 1.6 million people.

General Electric (GE)

General Electric (GE) is a leader in the industrial machinery market, known for its innovative solutions that significantly boost efficiency. The company’s advanced technologies and commitment to innovation cement its top position in the industry.

GE’s contributions to the market are a testament to its established dedication to driving progress and setting new standards.

Siemens

Siemens is a global leader in industrial machinery, focusing on advanced automation technologies that enhance efficiency and productivity. Its emphasis on cutting-edge solutions has made it a key player, continually pushing the boundaries of what’s possible in industrial machinery.

Hitachi

Hitachi, with a strong presence in the industrial machinery market, recently reported sales of $8.8 billion. Its innovative technologies and applications have solidified its position as a major player. Hitachi’s commitment to excellence and innovation continues to drive its success and influence.

Challenges Faced by Machinery Manufacturers

Machinery manufacturers face numerous challenges in today’s competitive market. Supply chain disruptions, technological advancements, and regulatory compliance require navigation of a complex landscape to remain successful. Overcoming these challenges is key to maintaining efficiency, meeting customer expectations, and ensuring sustainability.

Supply Chain Disruptions

Shipping large machinery is inherently complex due to the size and scale of the equipment. Logistics challenges include handling oversized and heavy equipment, route planning considering road restrictions, bridge weight limits, and clearance heights.

These factors make supply chain disruptions a significant issue for machinery manufacturers.

Technological Advancements

The machinery manufacturing sector faces immense pressure to innovate to stay competitive. Increasing efficiency demands, environmental regulations, and digital transformation drive manufacturers to adopt new technologies like automation, IoT, and smart machinery.

These advancements boost productivity and ensure sustainability in manufacturing practices.

Regulatory Compliance

Regulatory challenges are increasingly significant for machinery manufacturers. Compliance with stringent environmental regulations requires practice adaptation. Different regions have specific requirements for transporting oversized loads, including permits, escort vehicles, and transit times.

These regulations add complexity to the manufacturing process.

How Technology is Shaping the Future of Machinery Manufacturing

Technology drives the transformation of the machinery manufacturing industry. Automation, robotics, IoT, and sustainable practices reshape how machinery is designed, produced, and operated.

Key technological trends are setting the stage for the future of machinery manufacturing.

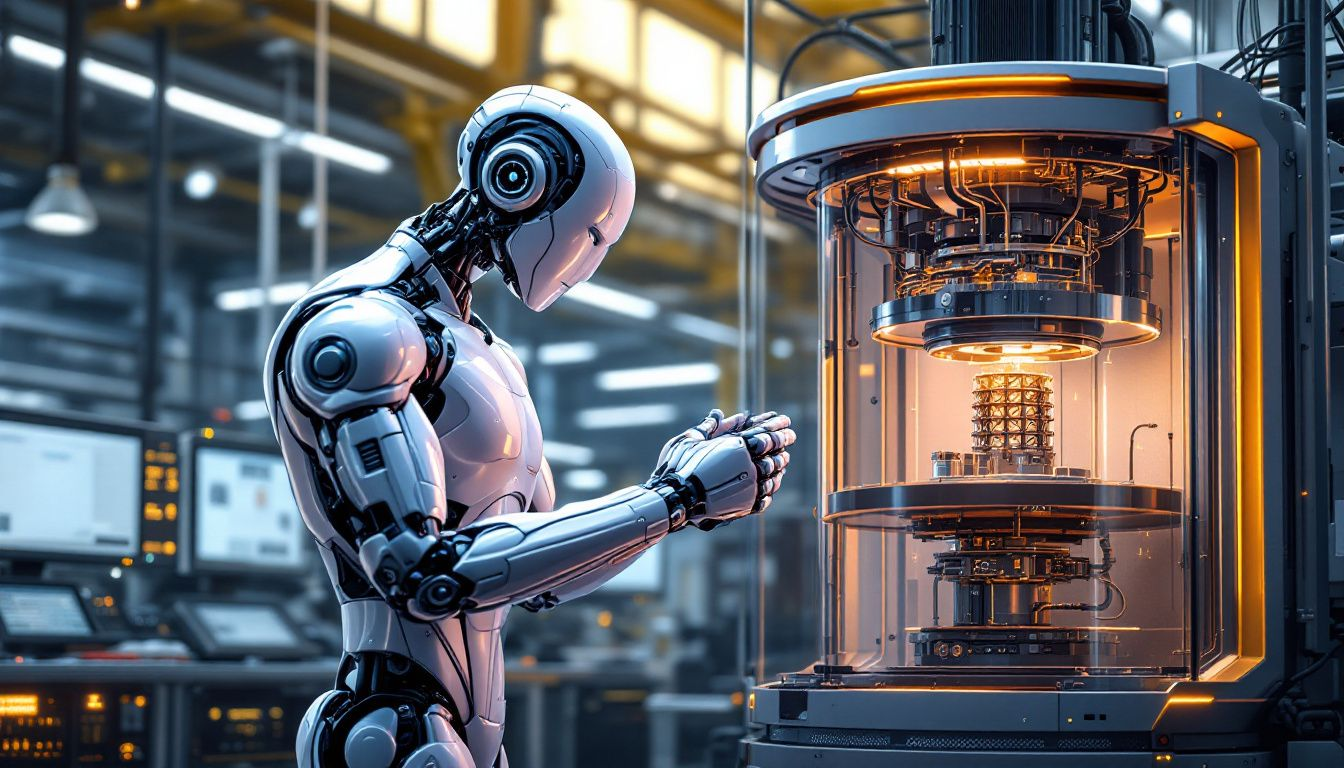

Automation and Robotics

Automation and robotics revolutionize manufacturing processes, enhancing efficiency and productivity. Case IH leads these advancements in agricultural applications, utilizing ISOBUS technology to enhance precision farming.

Robots designed for collaborative tasks safely operate alongside humans, adapting to their presence and further modernizing the industry.

IoT and Smart Machinery

The Internet of Things (IoT) interconnects machinery, facilitating real-time data exchange and monitoring. This interconnectedness enhances operational efficiency, allowing manufacturers to optimize performance and maintenance schedules.

Integrating smart technologies transforms machinery operations, making processes more efficient and reducing downtime.

Sustainable Manufacturing Practices

Sustainability is becoming a cornerstone of modern manufacturing practices. Machinery manufacturers increasingly adopt sustainable practices to minimize their environmental footprint and contribute to a greener economy. This includes implementing recycling programs, using sustainable materials, and investing in energy-efficient technologies to reduce waste and lower operational costs.

Global Market Trends in Machinery Manufacturing

Various trends influence the global machinery manufacturing market, including emerging markets’ rise, increased demand for customization, and the impact of trade policies. These trends shape manufacturers’ strategies and operations, driving them to innovate and adapt to changing market dynamics.

Growth in Emerging Markets

Emerging markets present significant growth potential for machinery manufacturers, driven by rising demand and economic development. These markets are becoming key players in the sector, offering new opportunities for expansion and innovation.

Increased Demand for Customization

The shift towards tailored machinery solutions reshapes manufacturing processes to better meet specific customer needs. This trend requires manufacturers to adopt flexible techniques, allowing them to produce customized products catering to diverse requirements.

Impact of Trade Policies

Trade policies heavily influence machinery manufacturing, affecting supply chains, tariffs, and market access. These policies can disrupt global supply chains, requiring adaptation to new sourcing strategies and navigation through varying regional regulations. Tariffs from trade agreements can increase production costs, impacting pricing strategies and market competitiveness.

How to Choose the Right Machinery Manufacturer

Choosing the right machinery manufacturer involves considering factors like product quality, after-sales support, and cost versus value. Understanding your specific needs and researching potential candidates based on their reputation and offerings is crucial for an informed decision.

Assessing Product Quality

Evaluating product quality is crucial when selecting a machinery manufacturer. Ensure the equipment meets industry standards and has necessary certifications. Advanced technologies like machine vision and spectroscopy can assist in assessing the quality of agricultural machinery.

Consider materials used, durability, and product reviews from current users to make an informed decision.

Evaluating After-Sales Support

Reliable after-sales support is crucial for maintaining machinery performance. Effective service includes timely maintenance, repairs, and parts availability. Prompt technical assistance and a reliable supply of replacement parts significantly influence the overall experience with the manufacturer.

Considering Cost vs. Value

Balancing machinery cost with overall value is vital for informed purchasing decisions. Compare prices and assess the overall benefits and longevity of the machinery when making a sell.

Consider factors like the quality of materials used, the level of after-sales support, and the potential for future upgrades to ensure the investment provides long-term value.

Summary

In conclusion, the machinery manufacturing industry is shaped by leading companies that drive innovation and set standards across construction, agriculture, and industrial sectors. Navigating the challenges of supply chain disruptions, technological advancements, and regulatory compliance is essential for these manufacturers to stay competitive. Technological trends such as automation, IoT, and sustainable practices are pivotal in shaping the future of the industry. Understanding global market trends and selecting the right manufacturer based on product quality, after-sales support, and cost versus value are crucial steps for consumers. As we look to the future, the continued evolution and adaptation of machinery manufacturing will undoubtedly play a critical role in advancing various industries.

Frequently Asked Questions

Who are the leading manufacturers in the construction equipment sector?

Caterpillar, Komatsu, and Volvo Construction Equipment are the leading manufacturers in the construction equipment sector, known for their innovation and reliability. Selecting equipment from these brands can ensure quality and performance on your projects.

What technologies are driving innovation in agricultural machinery?

Technologies like IoT, AI, machine learning, and sensor integration are pivotal in driving innovation in agricultural machinery, significantly increasing efficiency and minimizing human error. Embracing these advancements is essential for the future of agriculture.

How do trade policies impact machinery manufacturing?

Trade policies significantly impact machinery manufacturing by altering supply chains and imposing tariffs, which can lead to increased production costs and disruptions in global market access. Consequently, manufacturers must navigate these complexities to remain competitive.

What factors should be considered when choosing a machinery manufacturer?

When selecting a machinery manufacturer, prioritize product quality, after-sales support, and the cost-to-value ratio to ensure you make a well-informed decision. This will ultimately impact your operational efficiency and long-term satisfaction.

What are some of the challenges faced by machinery manufacturers?

Machinery manufacturers encounter significant challenges like supply chain disruptions, the necessity for technological advancements, and stringent regulatory compliance. Addressing these issues is crucial for maintaining competitiveness in the market.