Gemma

AUTOCUT

AUTOCUT

Couldn't load pickup availability

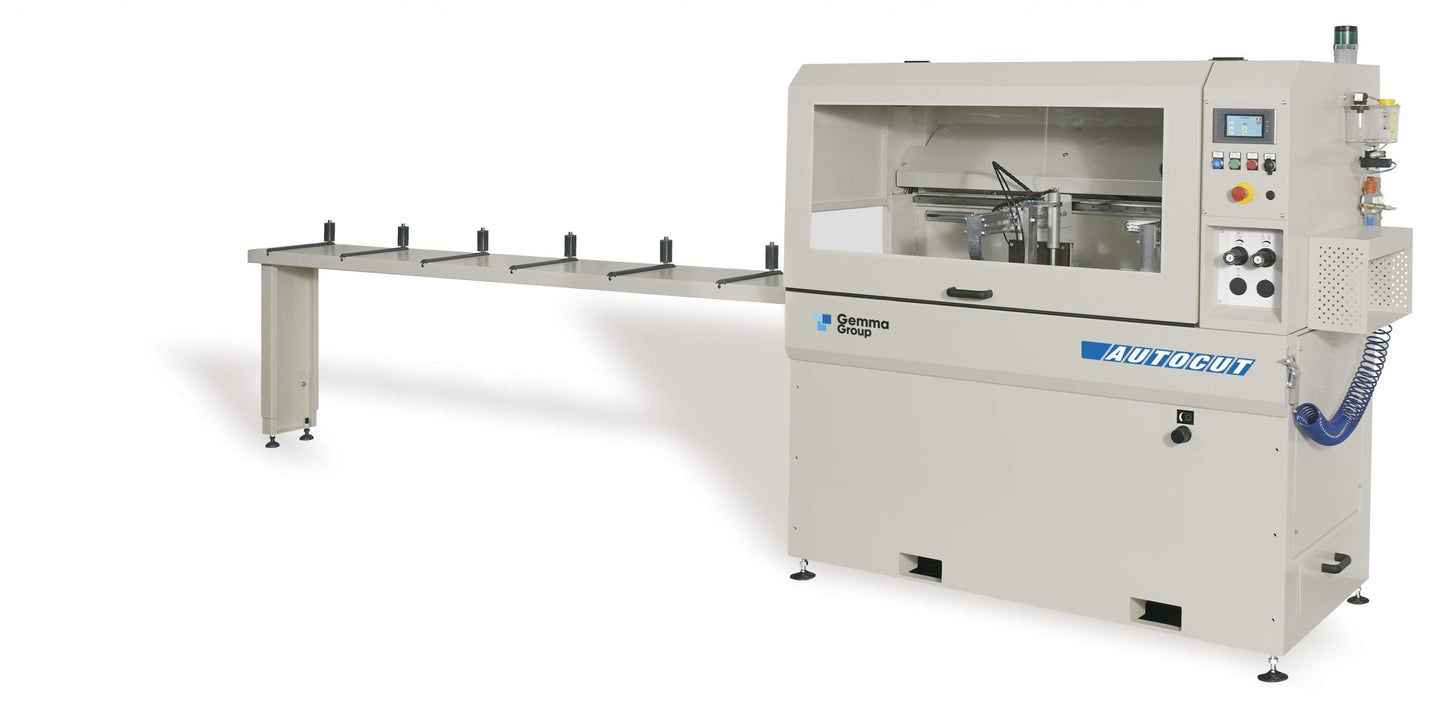

Autocut: High-Performance Automatic Cutting Machine for Aluminum Profiles

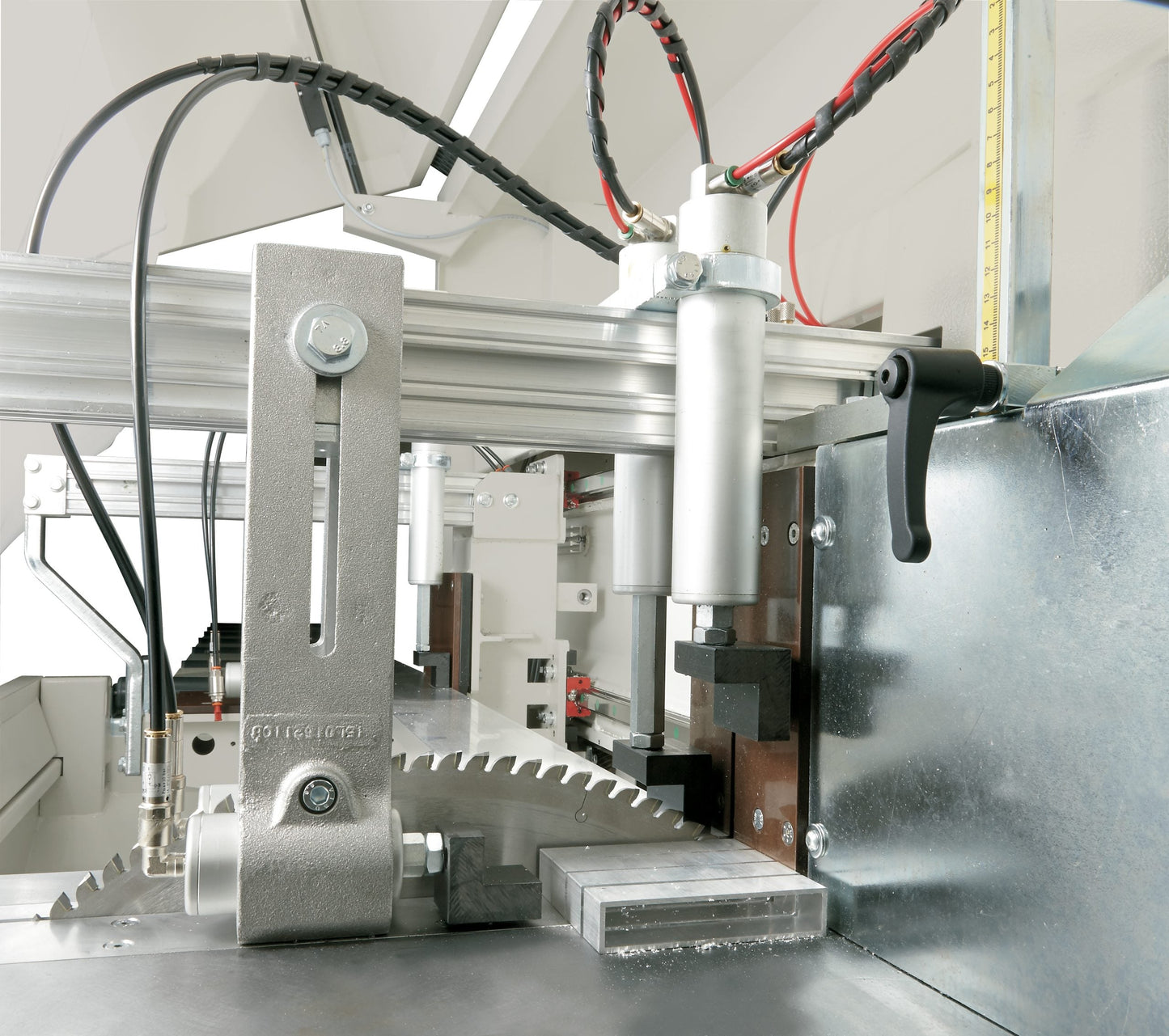

Single head miter saw with ascending blade for 90° cuts. Automatic piece feed. Base in ribbed electro-welded steel. Autocut it is equipped as standard with 4 horizontal pneumatic clamps, 3 vertical pneumatic clamps and a central support for small section profiles. Profile locking with extremely rigid "bridge" system. The cutting unit is controlled by a 5,5 kW motor at 2.800 rpm and is equipped with a widia blade diam. 550mm.

Cutting lubrication is atomised (Venturi system). Minimum cutting length 5 mm. Maximum cutting length 660 mm. Bar feed controlled by software, controlled by brushless motor with sliding on ground rack. Laser detector length of the end of the bar.

The operator interface is on PC-Windows with a 7” color touch-screen. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Share

Autocut: High-Performance Automatic Cutting Machine for Aluminum Profiles

Revolutionizing Precision Cutting with Autocut

The Autocut single-head cutting-off machine is the ultimate solution for precise and efficient aluminum profile cutting. Designed exclusively for 90° cuts, this state-of-the-art equipment combines high speed, high accuracy, and simple operation to meet the demands of modern industrial workflows.

Key Features and Benefits

Robust Structure:

An electro-welded steel basement ensures durability, while horizontal and vertical clamps securely lock profiles for consistent cutting quality.

Advanced Cutting Unit:

Equipped with a high-performance 550 mm widia blade for precise, burr-free cuts, ensuring an excellent cutting surface with minimal flatness errors.

Blade output management via an oleopneumatic mechanism optimizes cutting time and minimizes wear.

Automatic Feeding:

A bar advancement system powered by a brushless motor, ensuring smooth, efficient feeding with precision up to ± 0.25 mm.

Handles cutting lengths ranging from 5 mm to 660 mm with ease.

Enhanced Control:

Operate via a 7” color touch-screen with Windows PC integration.

Program cutting lists and monitor progress using advanced connectivity options, including Ethernet, WiFi, and USB ports.

Integrated Cooling Systems:

A Venturi lubrication system maintains blade performance and boosts cutting quality.

Safety First:

Fully enclosed cutting area with automatic protections complies with CE safety standards for operator safety.

Superior Cutting Capabilities

Maximize efficiency with a cutting speed of 6 m/min and a positioning speed of 30 m/min.

Accommodates large aluminum profiles up to 160x160 mm and 300x120 mm.

Optional Add-Ons

Micro-drop lubrication for enhanced performance.

Extended loading roller conveyors for streamlined material handling.

Spare widia blades and custom setups for USA-CANADA standards.

Technical Specifications

Power Supply: 400 V / 50 Hz

Motor Power: 5.5 kW

Compressed Air: 7 Bar, 25 Nl/cycle

Blade Speed: 2,800 rpm

Data Import and Control

The Autocut cutting machine excels in data import and control, offering seamless integration with various software systems. Whether through software docking, network connections, USB flash disk import, or manual input, transferring cutting settings and profiles to the machine is effortless. The user-friendly control panel, featuring an intuitive interface, allows operators to navigate and adjust settings with ease. This ensures precise cutting and optimal performance, making the Autocut a cutting machine that truly stands out in its class.

Industrial Applications

Designed for versatility, the Autocut cutting machine is perfect for a wide range of industrial applications. From window and door manufacturing to storefront and curtain wall fabrication, this machine handles it all with high-speed cutting and precise accuracy. It’s also an excellent choice for commercial aluminum supply and automotive production, where high-quality aluminum profiles are essential. The machine’s ability to cut complex profiles and angles makes it suitable for general production and residential applications, showcasing its remarkable ability to meet diverse industry needs.

Safety and Reliability

Safety and reliability are at the forefront of the Autocut cutting machine’s design. The fully enclosed cutting unit protects operators from debris and noise, ensuring a safer and more environmentally friendly workspace. The automatic lubrication and cooling systems prolong the operating time of the saw blade, maintaining optimal performance. Additional safety features, such as emergency stop buttons and a protective cover, provide an extra layer of security for operators, making the Autocut a reliable and safe choice for any cutting task.

Maintenance and Support

The Autocut cutting machine is engineered for easy maintenance and robust support. Its simple and fast operation process ensures that users can quickly become proficient in its use. The easily accessible control and electrical panels facilitate swift troubleshooting and repairs. The manufacturer offers comprehensive support and training programs, helping operators maximize the machine’s potential. Regular maintenance and support not only extend the machine’s lifespan but also ensure it consistently delivers optimal performance, making the Autocut a dependable asset in any production environment.

Why Choose Autocut?

The Autocut machine stands out for its high accuracy, ease of use, and reliability. It’s the perfect profile cutting machine for industries aiming to enhance productivity and maintain superior quality standards. With advanced features like adjustable blade output, network connectivity, and user-friendly controls, Autocut simplifies complex cutting tasks while ensuring exceptional results.