Gemma

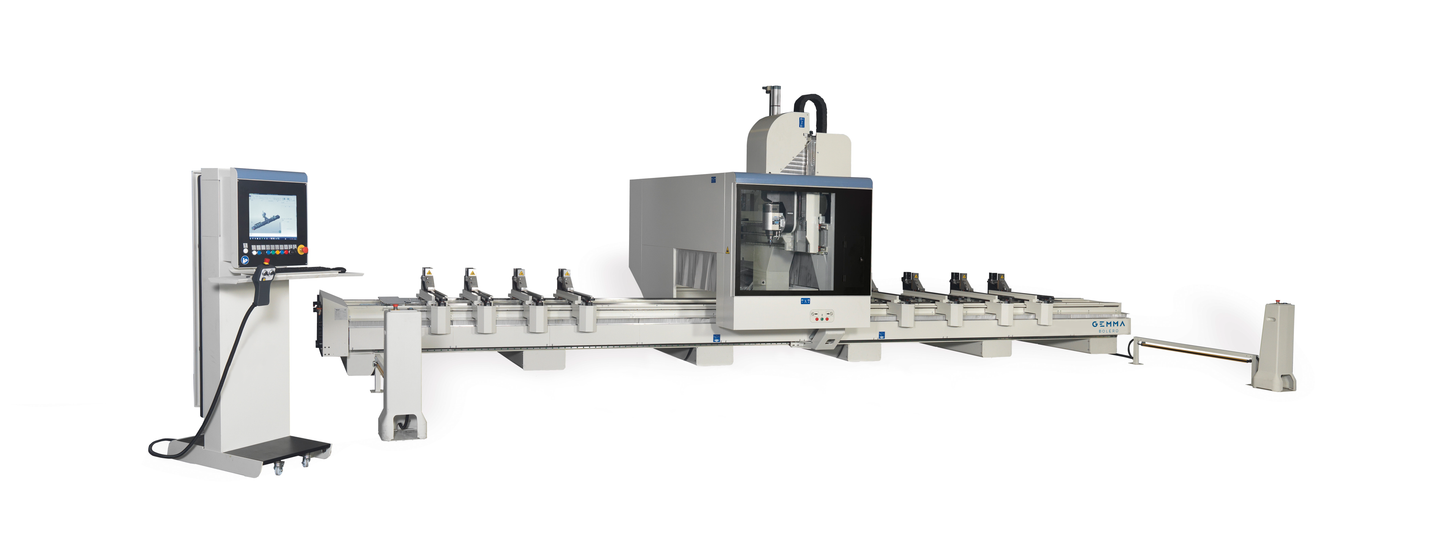

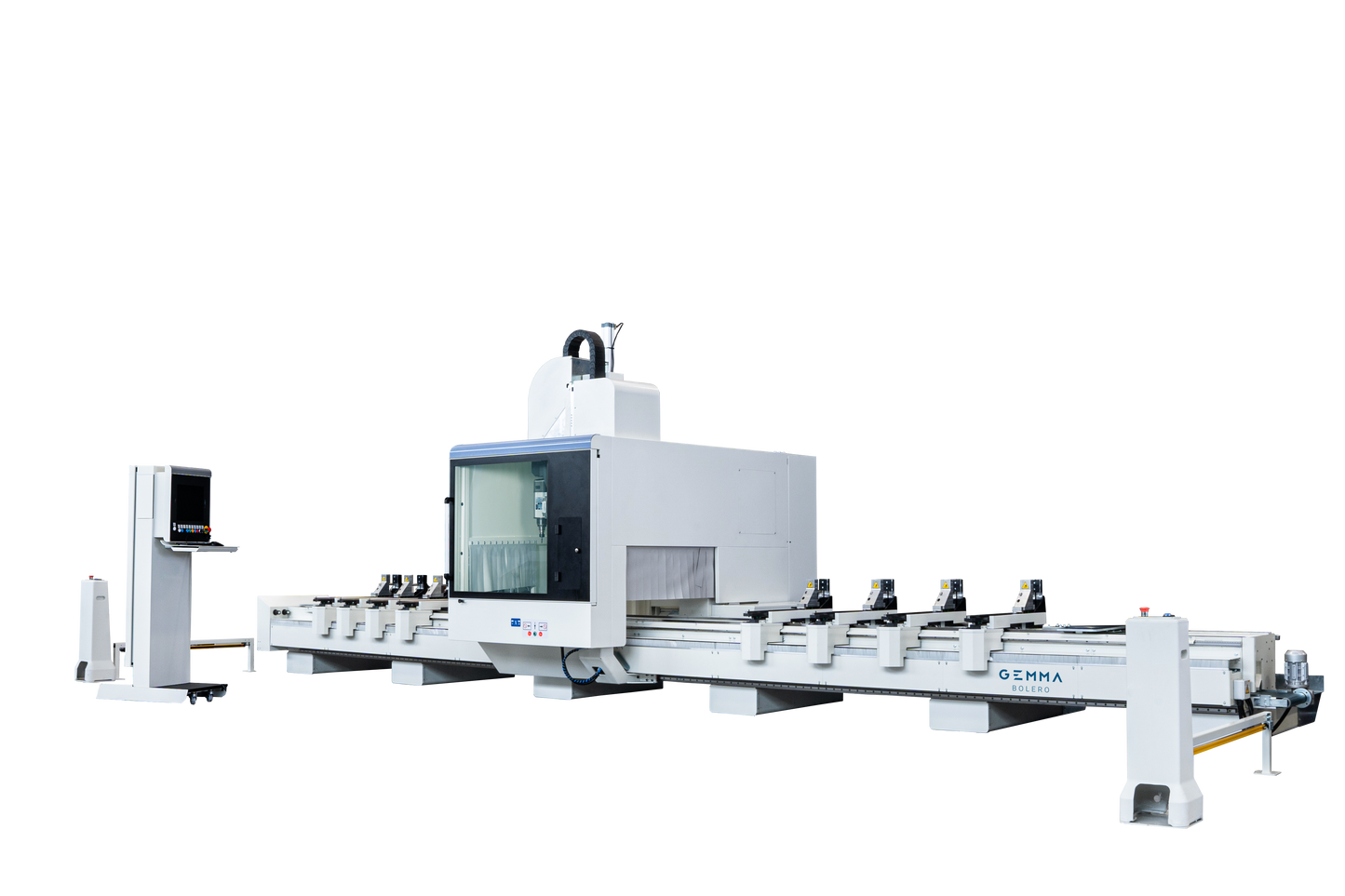

BOLERO 4

BOLERO 4

Couldn't load pickup availability

BOLERO 4: The 4 Axis Machining Center for Aluminum profiles

Machining center with 4 NC-controlled axes for machining components in aluminium, steel, light alloys and PVC. The machine has a strongly ribbed base in electro-welded steel with a mobile upright with a closed bridge.

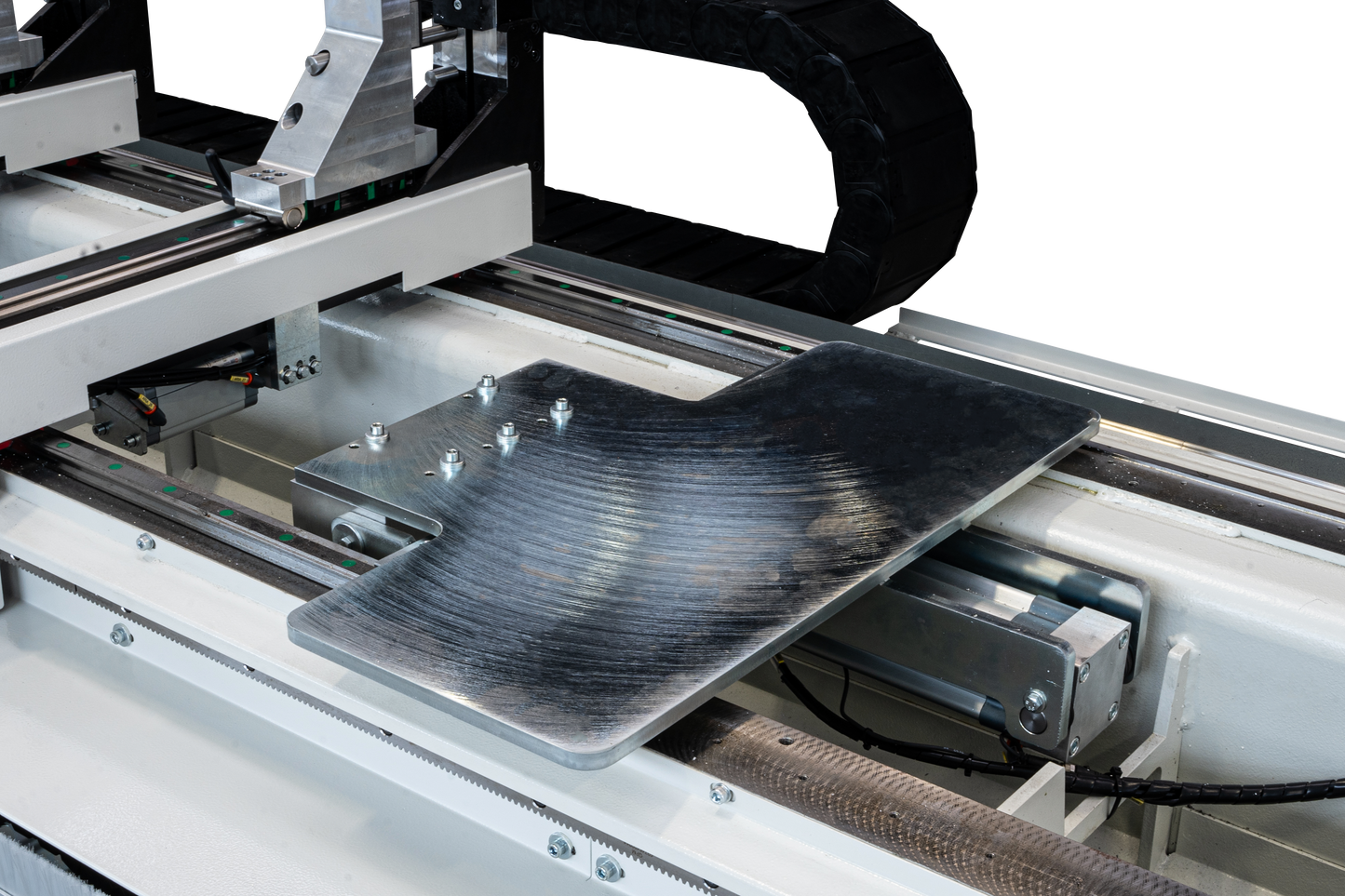

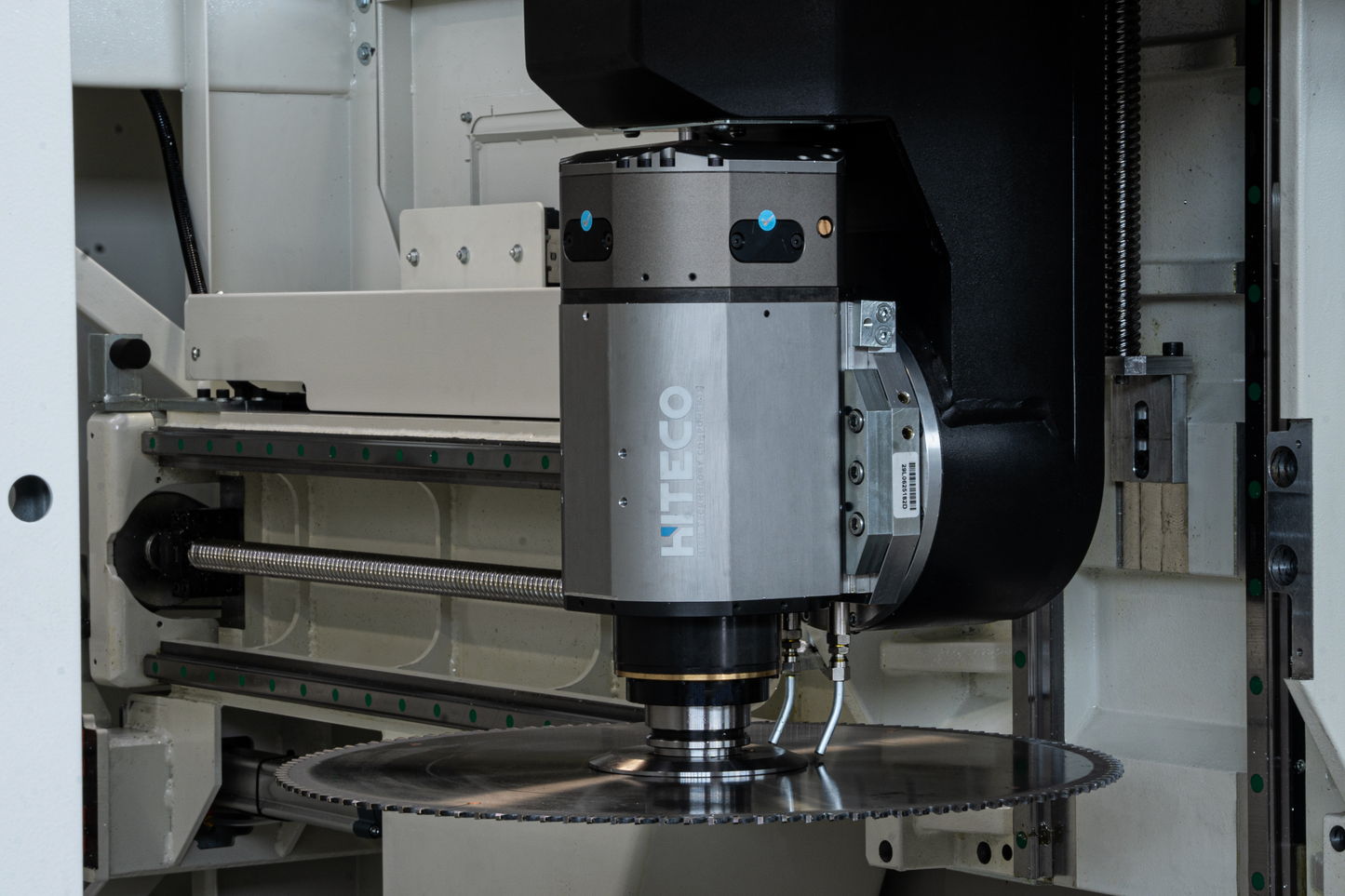

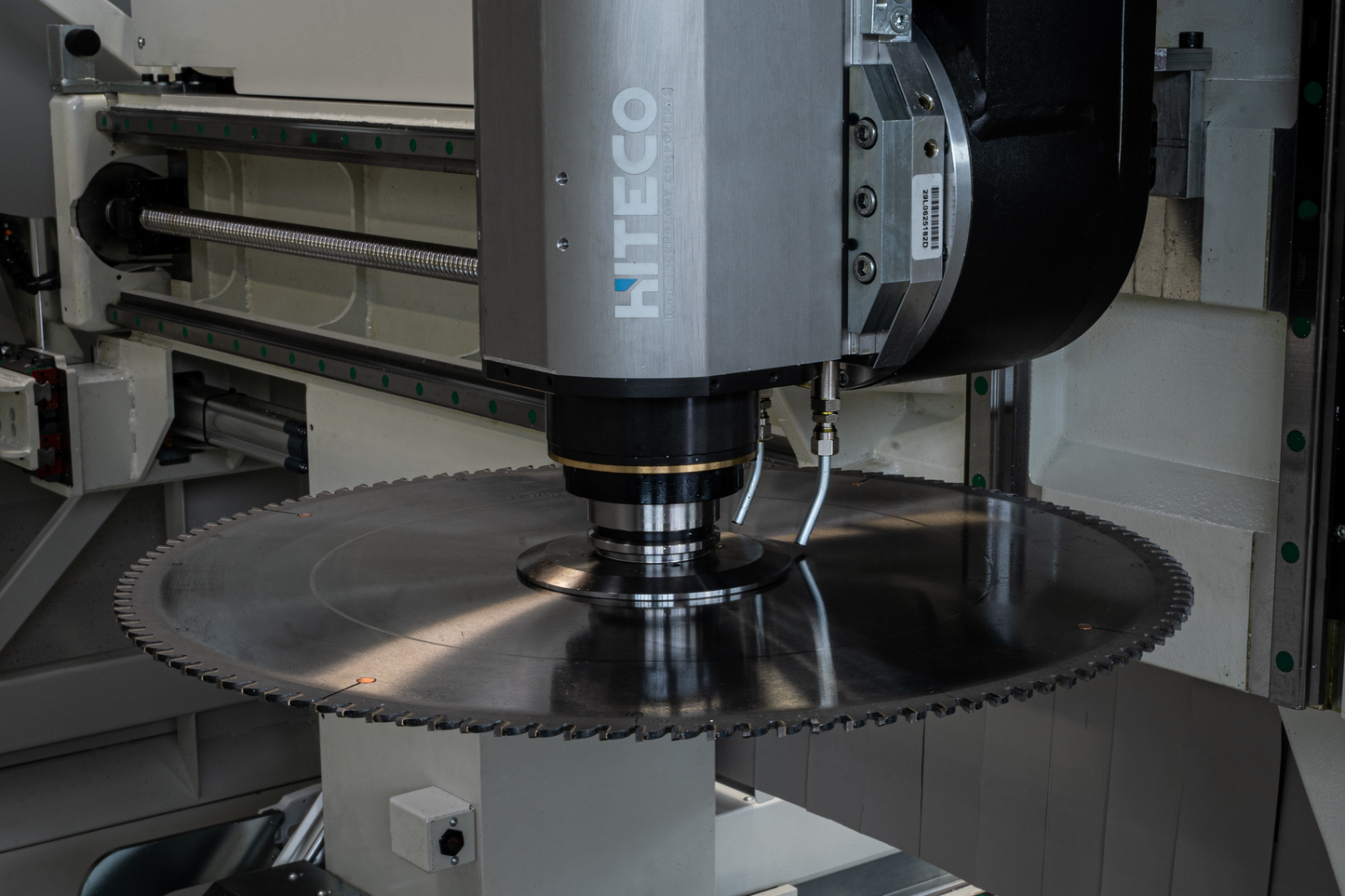

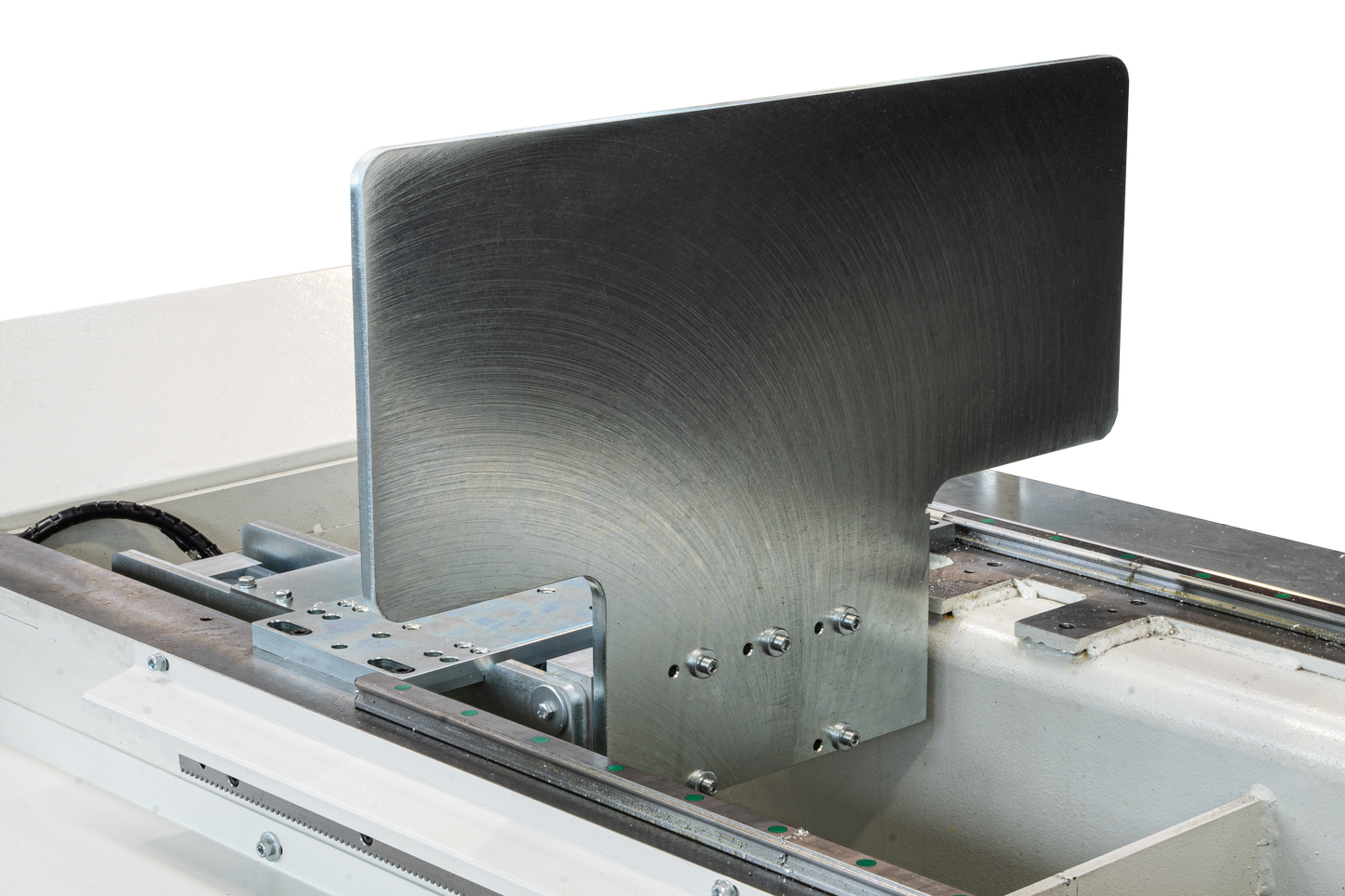

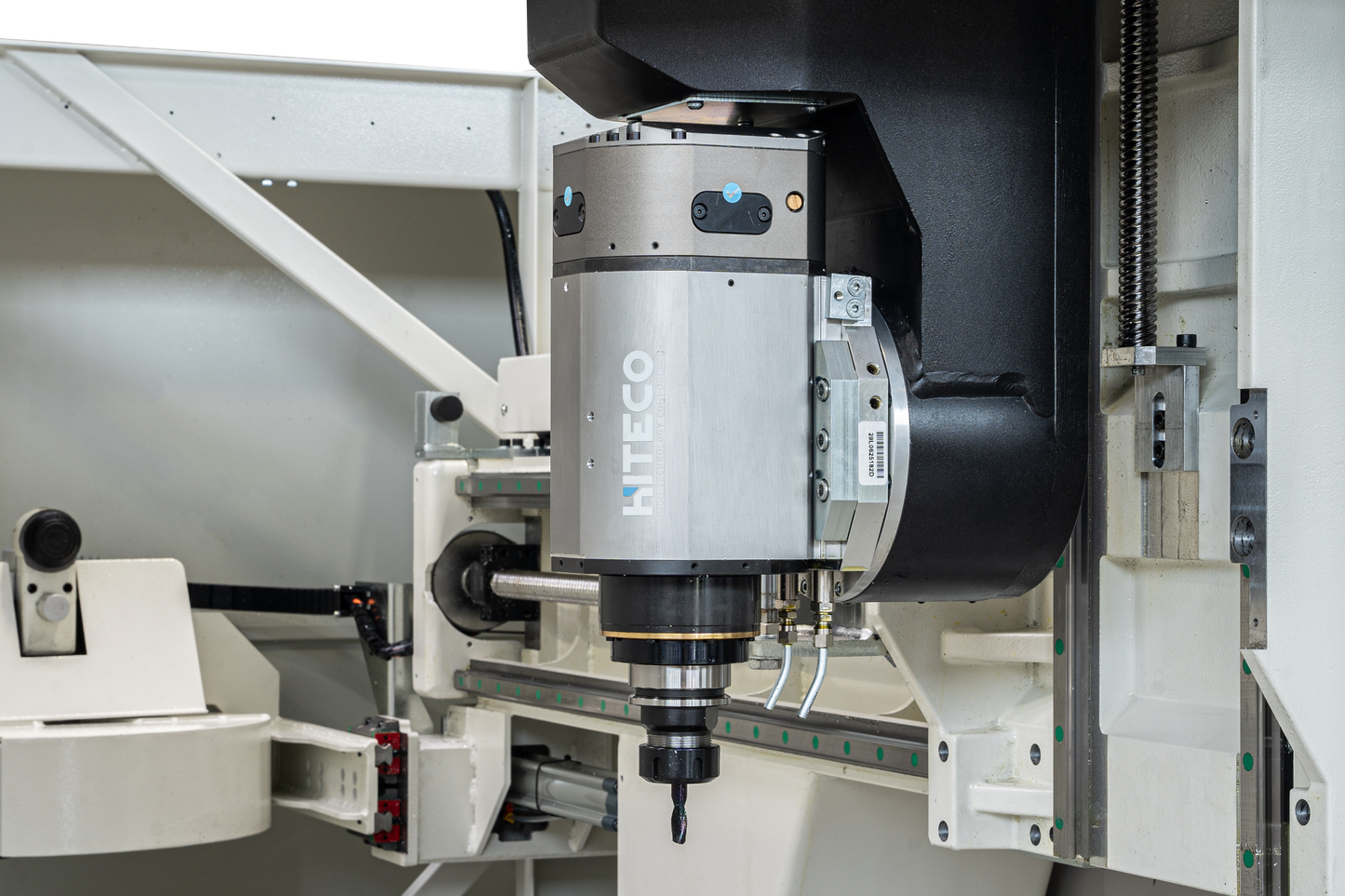

Thanks to its sturdiness and stability, it guarantees high quality workmanship and reliability over time. The operating group is made up of an 8,5 kW electrospindle and is equipped as standard with an ISO30 tool attachment which is also functional for carrying out heavy machining. The maximum rotation speed is 24.000 rpm with regulation by static inverter. Bolero 4 is equipped with an automatic tool changer with a 12-position magazine. The worktable is equipped as standard with 8 locking vices with automatic movement by means of a head controlled by the NC.

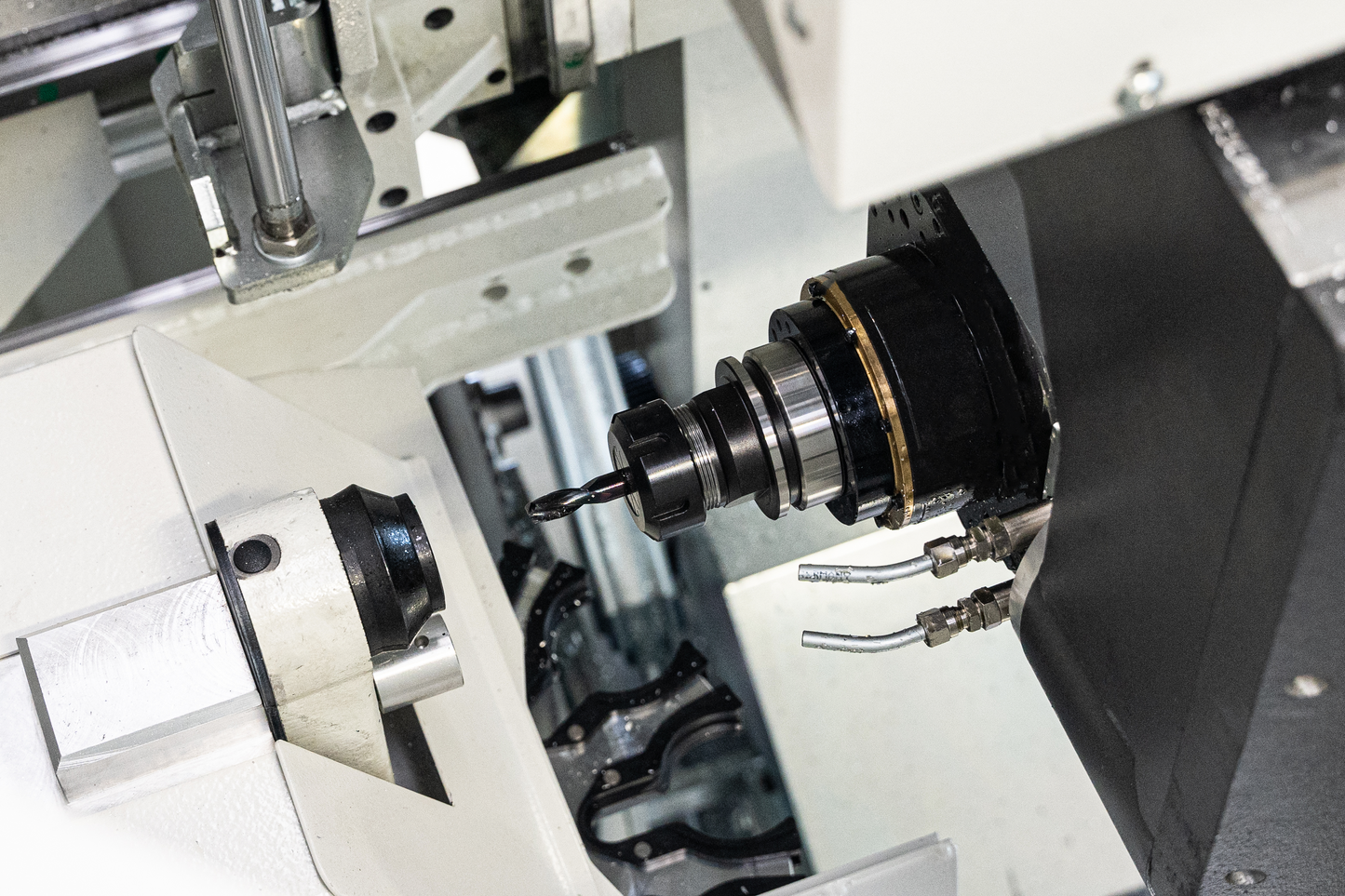

The milling head of the Bolero 4 is designed for high performance, featuring precision, power, and speed. It employs advanced technologies such as air-cooling and a tool changing system, enhancing the machine's ability to efficiently process various materials, particularly aluminum profiles.

The X-axis stroke is 7.000 mm (optional extension up to 9.400 mm). Pendulum machining is possible (optional). The operator interface is on PC-Windows with a 17” screen. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Share

Collapsible content

Bolero 4 – The Advanced 4-Axis Machining Center for Precision and Efficiency

The Bolero 4 is a cutting-edge 4-axis CNC machining center engineered for the milling and drilling of aluminum profiles, PVC, light alloys, and steel. Designed with a focus on high precision, durability, and flexibility, this machine is a vital addition to industries that demand top-tier machining accuracy and efficiency.

Key Features of the Bolero 4 Axis CNC

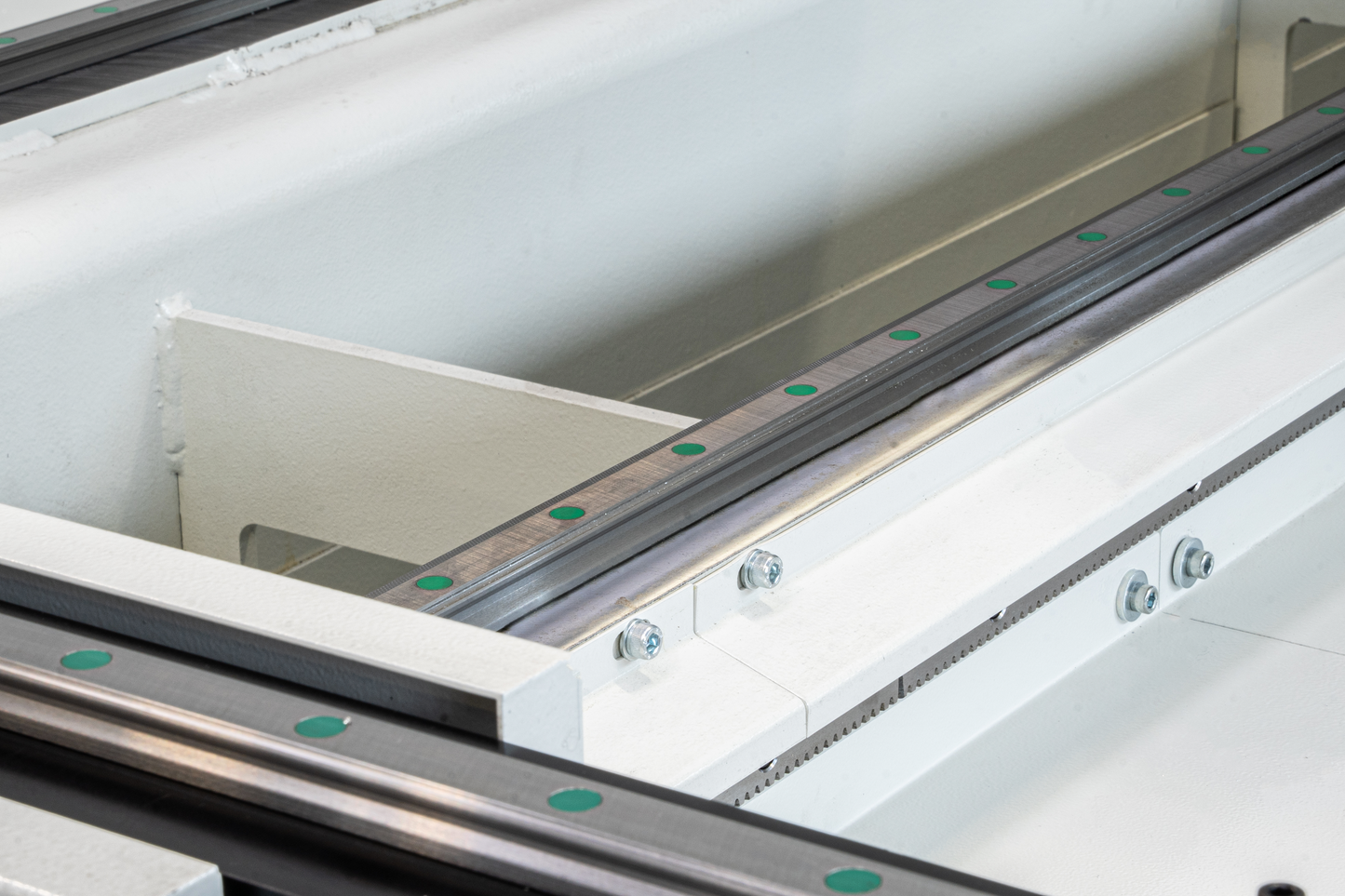

- Robust Design for Reliability:The heavily ribbed, electro-welded steel structure ensures high rigidity, supporting long-lasting reliability and consistent machining quality.

- Advanced Electrospindle Technology:Equipped with a compact electrospindle featuring ISO30 taper, high-precision ceramic bearings, and an inverter for precise speed control, the Bolero 4 delivers outstanding performance and flexibility for diverse operations.

- Intelligent Control System:Powered by the OSAI control interface with HICAM 2 software, the Bolero 4 simplifies the upload and execution of machining programs, enabling seamless workflow management. With Industry 4.0 compatibility, it supports remote monitoring and wifi connectivity.

- Dynamic Axis Control:The Bolero 4 features precision ball screws, brushless motors, and automatic grease lubrication, ensuring smooth movement across X, Y, and Z axes for high-speed machining. The pivoting A-axis provides ±120° flexibility for complex geometries.

- High-Efficiency Tool Handling:An automatic tool changer with a 12-position magazine minimizes downtime, making it ideal for operations like end milling, grooving, drilling, and tapping. The Bolero 4 can also perform drilling operations on materials like aluminum and steel profiles, showcasing its versatility and efficiency.

Technical Highlights: Servo Motors

- Working Area Dimensions:

- X-axis stroke: 7,000–9,400 mm

- Y-axis stroke: 1,300 mm

- Z-axis stroke: 670 mm

- Speed & Precision:

- Positioning accuracy: ±0.2 mm

- Repeatability: ±0.1 mm

- X-axis speed: 100 m/min

- Electrospindle Performance:

- Power: 8.5 kW

- Speed: 1,000–24,000 rpm

- Tool magazine capacity: 12 positions

- Material Compatibility:Utilizing advanced machining centers, process a wide range of materials, including aluminum profiles, PVC, light alloys, and steel.

Optional Enhancements

Customize your Bolero 4 with options like:

- Extended length configurations

- Motorized clamps for enhanced handling

- RTCP device for realigning axes

- Advanced software licenses for CAD and CAM integration

Applications of Bolero 4

The Bolero 4 is a versatile 4-axis CNC machining center designed to perform a wide range of applications, including:

- Milling and Drilling Operations on Aluminum Profiles: The Bolero 4 excels in processing aluminum profiles with high precision and speed, making it ideal for intricate milling and drilling tasks.

- End Milling and Tapping Operations on PVC Profiles: With its robust capabilities, the Bolero 4 can handle end milling and tapping operations on PVC profiles, ensuring clean and accurate cuts.

- Machining of Light Alloys and Other Materials: Whether working with light alloys or other materials, the Bolero 4 delivers consistent performance and high-quality results.

- High-Speed Machining of Complex Profiles: The machine’s advanced technology allows for high-speed machining of complex profiles, reducing production time without compromising accuracy.

- Heavy-Duty Machining of Large Profiles: Designed for heavy-duty applications, the Bolero 4 can handle large profiles with ease, maintaining high rigidity and precision.

The Bolero 4 is ideal for various industries, including aerospace, automotive, medical, and construction, where high accuracy and precision are required.

Industries Served by Bolero 4

The Bolero 4 serves a variety of industries, including:

- Aerospace: Machining of aluminum and light alloy profiles for aircraft and spacecraft components, ensuring high accuracy and reliability.

- Automotive: Machining of aluminum and steel profiles for vehicle components, such as engine blocks and gearboxes, with high speed and precision.

- Medical: Machining of aluminum and stainless steel profiles for medical equipment and implants, meeting stringent quality standards.

- Construction: Machining of aluminum and PVC profiles for building facades and architectural features, providing robust and aesthetically pleasing results.

The Bolero 4 is designed to meet the specific needs of each industry, with its high accuracy, high speed, and heavy-duty capabilities.

How to Use Bolero 4

Using the Bolero 4 is straightforward and efficient. Here’s a step-by-step guide:

- Load the Profile: Securely clamp the profile into the machine, ensuring it is properly positioned for machining.

- Select the Tool: Let the machine grab the right tool ou choose the appropriate tool and attach it to the spindle motor, ensuring a secure fit.

- Enter the Machining Program: Use the control terminal to input the machining program, specifying the desired operations such as milling, drilling, or tapping.

- Start the Machine: Initiate the machining process and monitor its progress, making adjustments as necessary to ensure optimal performance.

- Inspect the Finished Profile: Once the machining operation is complete, remove the profile from the machine and inspect it for accuracy and quality.

The Bolero 4 is designed for ease of use, with a user-friendly interface and intuitive controls.

Why Choose Bolero 4? High Accuracy!

The Bolero 4 stands out as a top-tier solution for 4-axis CNC machining with its unparalleled focus on speed, precision, and adaptability. Whether you're processing light alloys or heavy-duty steel, this machining center empowers operators with the tools to achieve optimal results in cutting-edge industries.

Bolero 4 Maintenance and Support

Regular maintenance is essential to ensure the Bolero 4 operates at optimal levels. Here are some tips:

- Clean and Lubricate: Regularly clean and lubricate the machine’s moving parts, such as the servo motors and linear guides, to ensure smooth operation.

- Check Tool Holders and Cutting Tools: Inspect and replace worn or damaged tool holders and cutting tools to maintain machining accuracy and quality.

- Perform Software Updates: Keep the machine’s control system current and efficient by performing routine software updates.

- Seek Support When Needed: Contact our support team for assistance with any technical issues or questions. Our team is available to provide maintenance, troubleshooting, and repair services.

We also offer training programs to help operators get the most out of their Bolero 4 machine, ensuring they can operate it efficiently and effectively.

Specifications at a Glance

The Bolero 4 delivers exceptional performance with its advanced features. Here's what sets it apart:

- Electrospindle Power: The machine is equipped with a powerful 8.5 kW electrospindle, ensuring reliable and efficient operations across a wide range of materials.

- Tool Magazine Capacity: With a 12-position automatic tool changer, it provides maximum flexibility for various machining operations.

- X-Axis Speed: Capable of speeds up to 100 meters per minute, the Bolero 4 is designed for fast and precise processing.

- Positioning Accuracy: Achieve outstanding results with a positioning accuracy of ±0.2 mm and repeatability of ±0.1 mm.

- Material Compatibility: This machining center is ideal for processing aluminum, PVC, light alloys, and steel, making it versatile for multiple industries.