Gemma

BOLERO 5

BOLERO 5

Couldn't load pickup availability

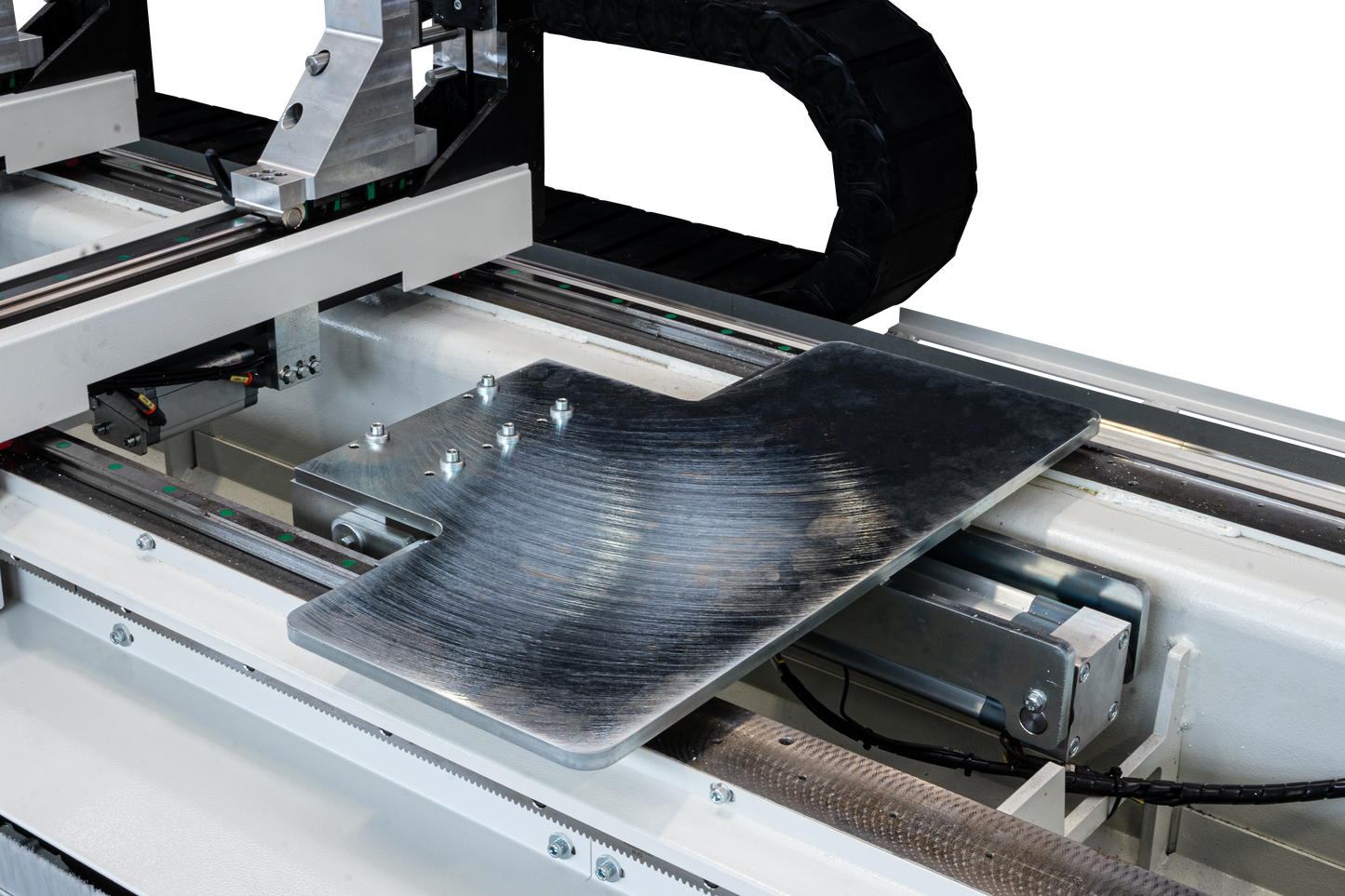

Machining center with 5 NC-controlled axes for machining components in aluminum, steel, light alloys and PVC. The machine has a strongly ribbed base in electro-welded steel with a mobile upright with a closed bridge. Thanks to its sturdiness and stability, it guarantees high quality workmanship and reliability over time. The operating group consists of a 17 kW electrospindle (S6) and is equipped as standard with an HSKF 63F tool holder which is also functional for carrying out heavy machining.

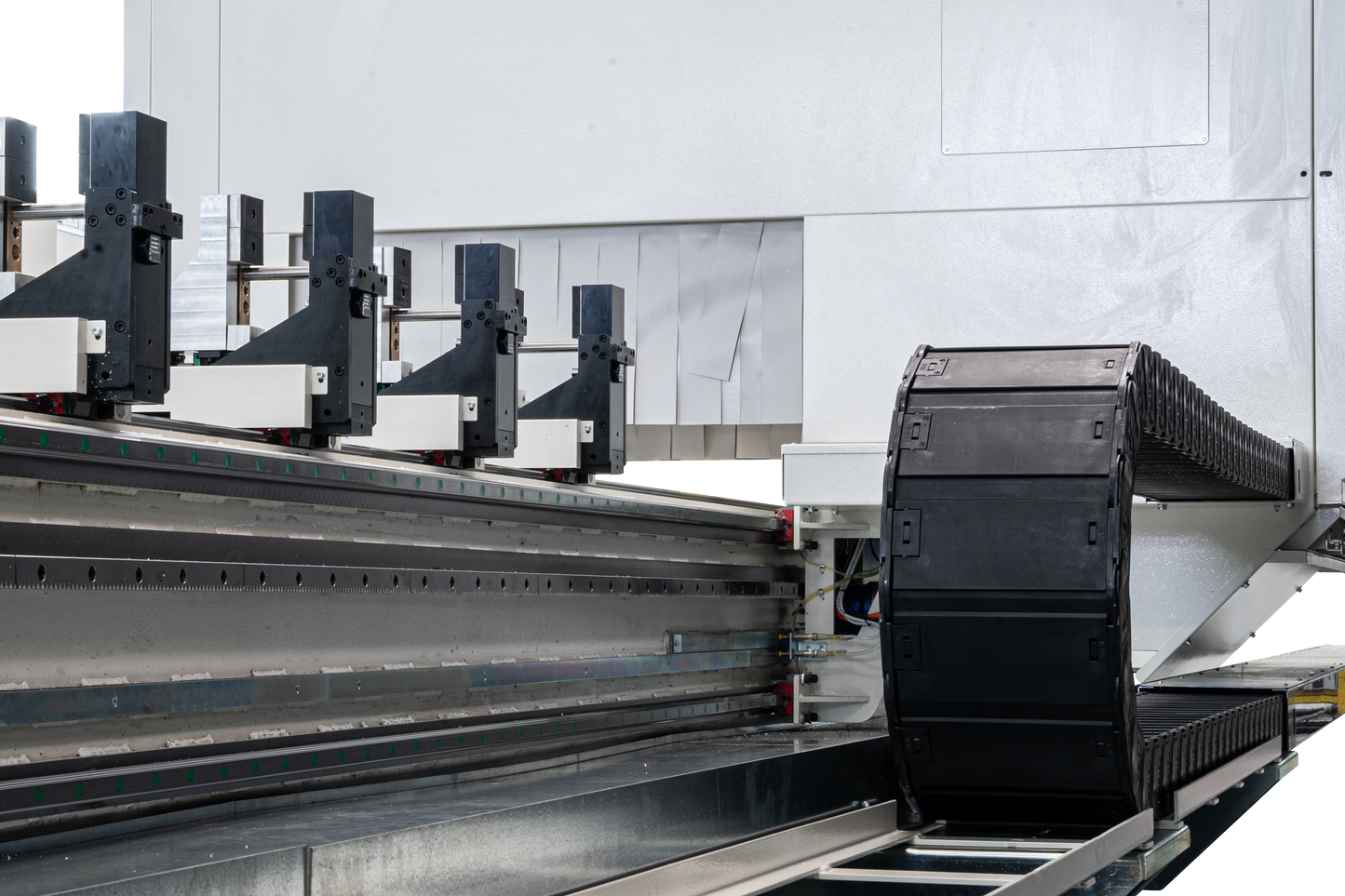

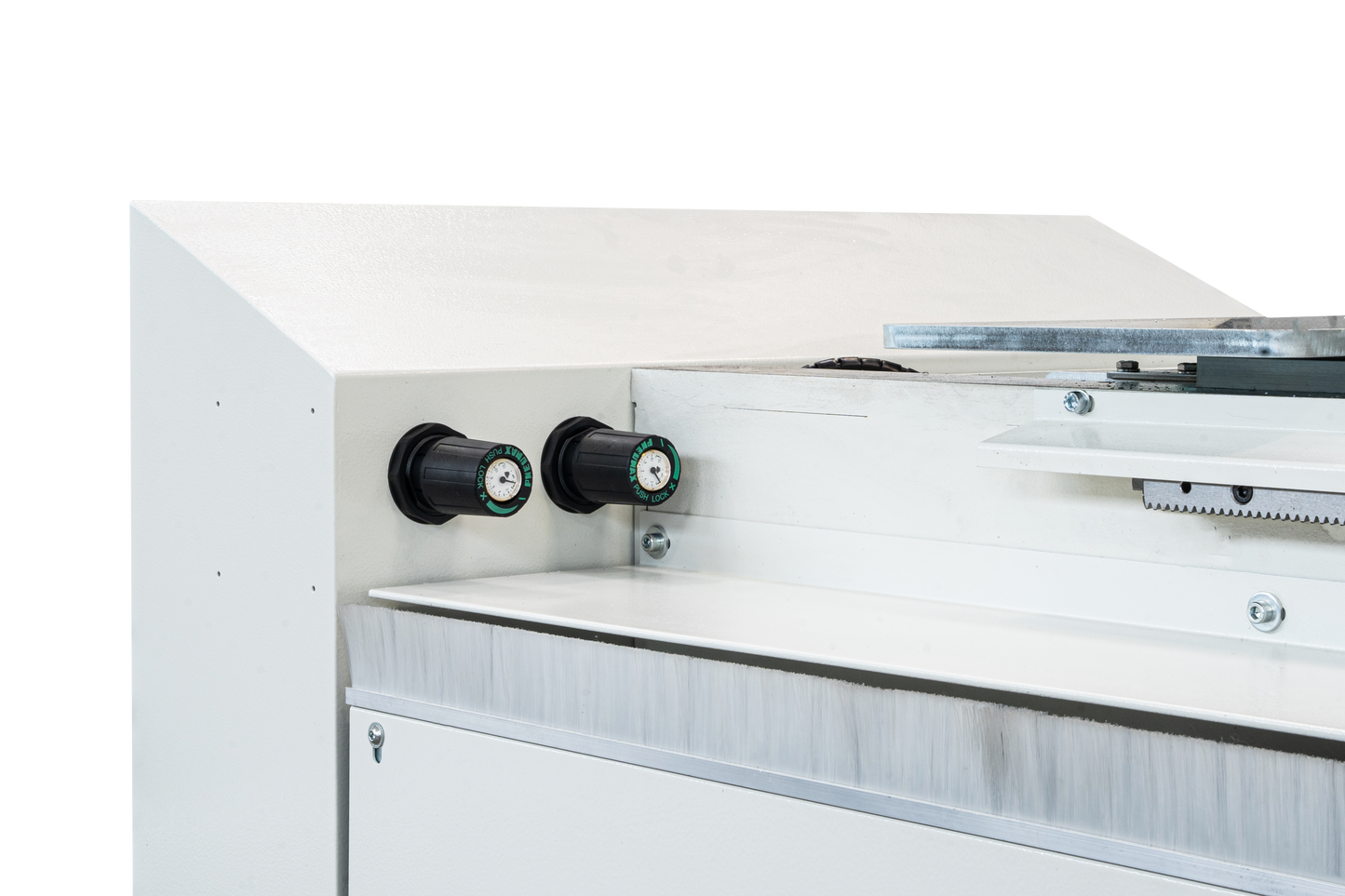

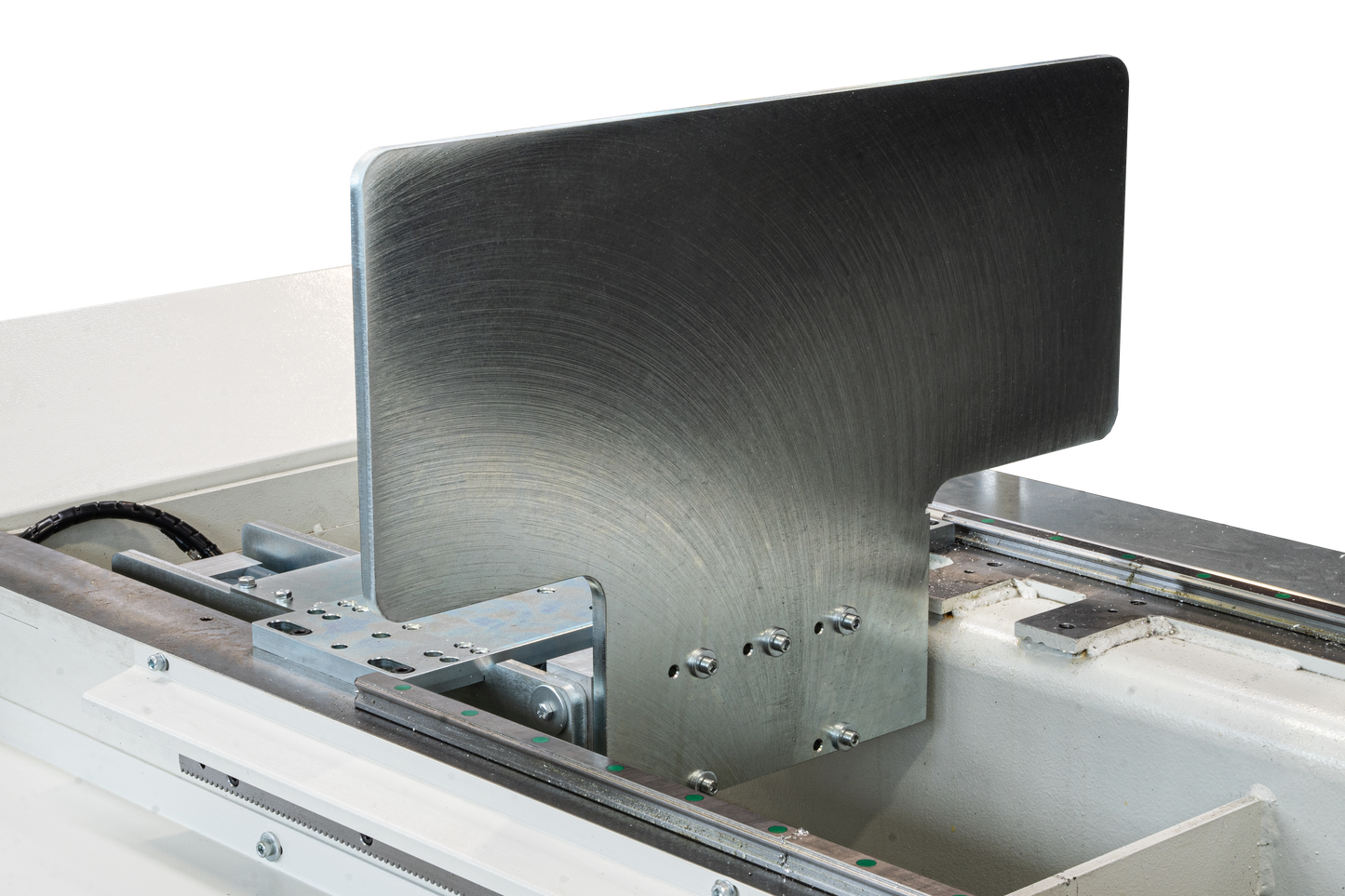

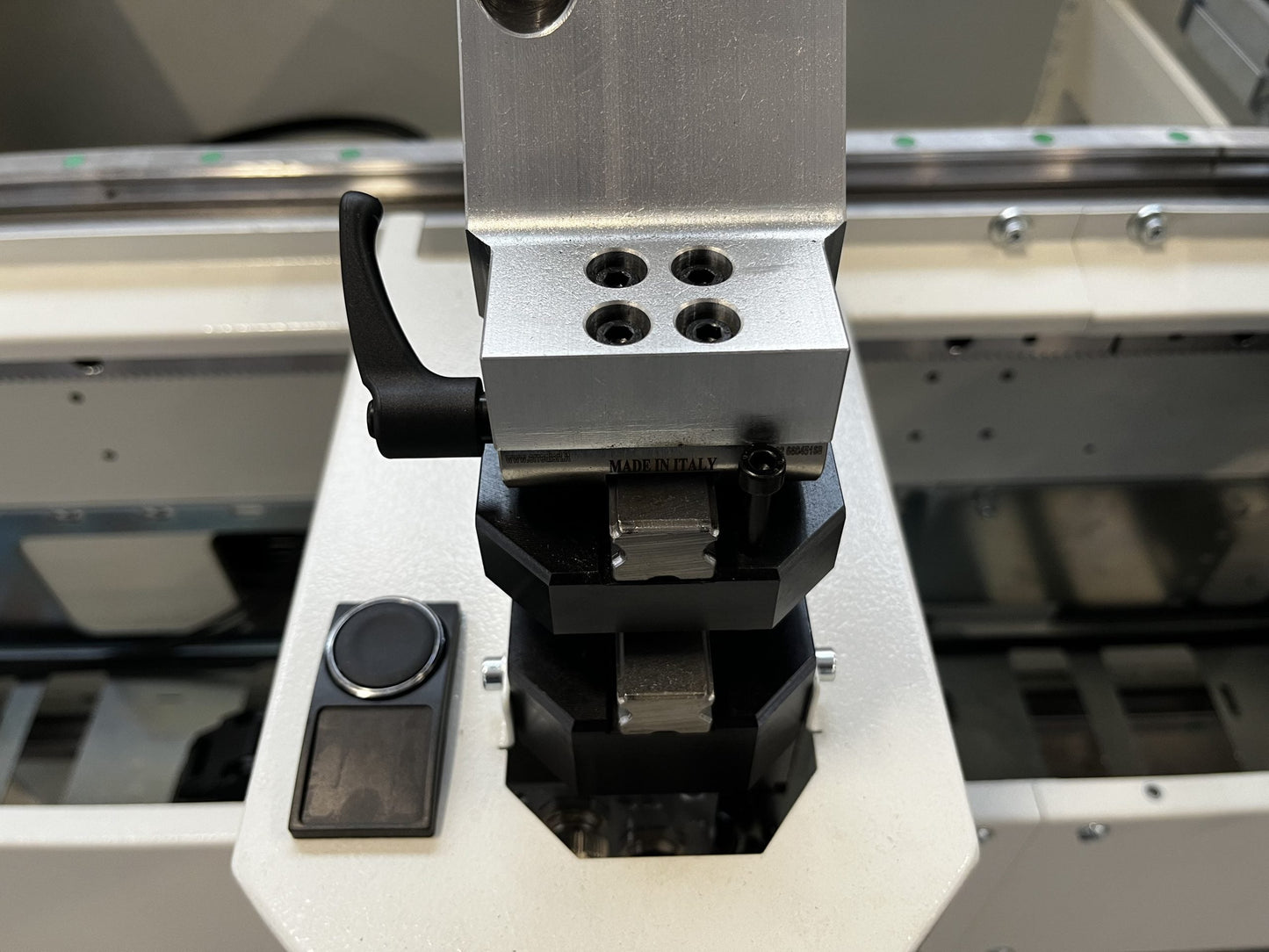

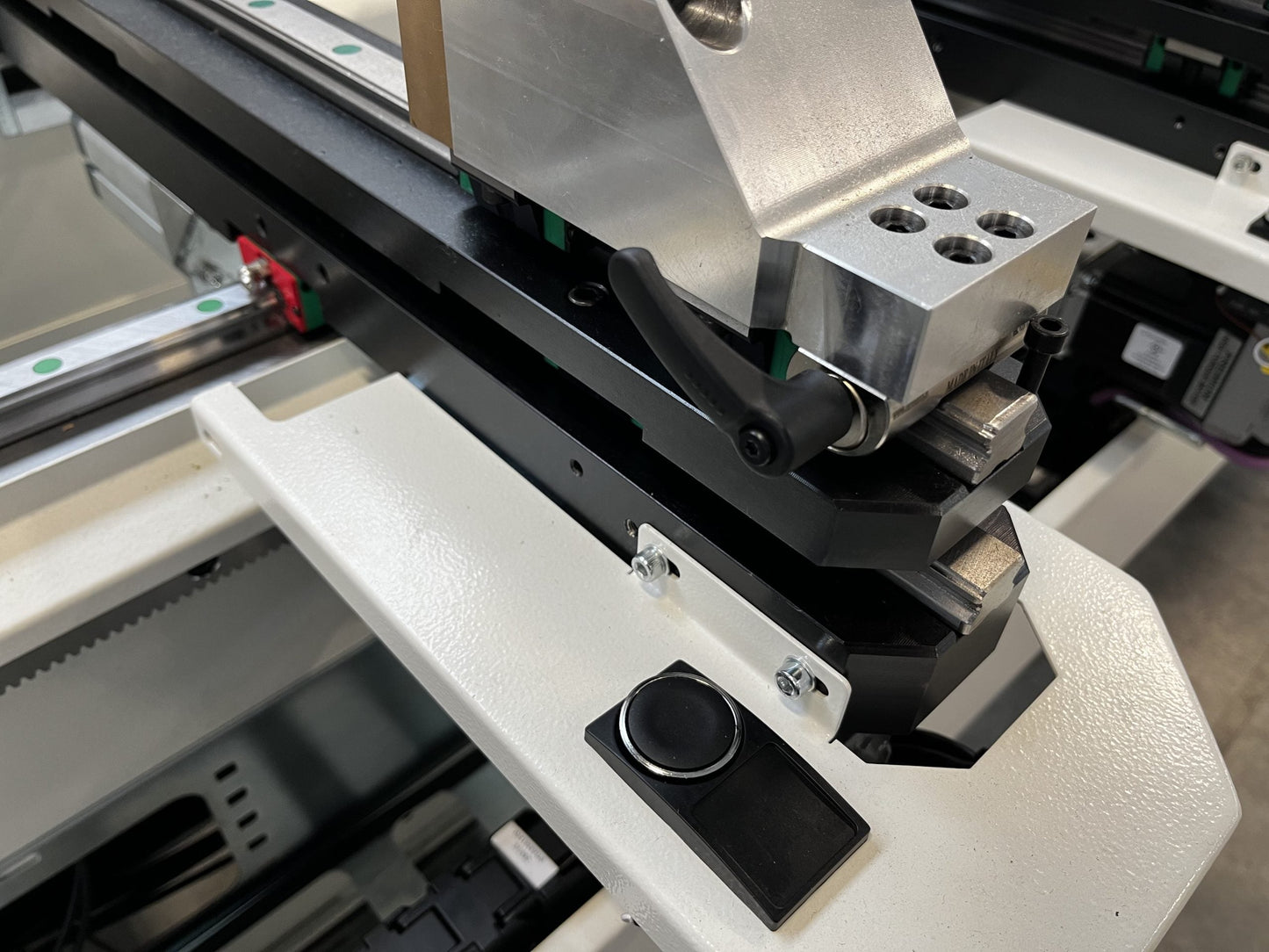

The maximum rotation speed is 24.000 rpm with regulation by static inverter. Bolero 5 is equipped with an automatic tool change device with a 12-position magazine and an additional magazine for a 500 mm blade. The worktable is equipped as standard with 8 motorized locking vices that can be positioned automatically with command from the NC.

The X-axis stroke is 7.000 mm (optional extension up to 9.400 mm). Pendulum machining is possible (optional). The operator interface is on PC-Windows with a 17” screen. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Share

Collapsible content

Bolero 5 - Precision in Every Dimension

The Bolero 5 is a state-of-the-art 5-axis machining center engineered for unparalleled precision and flexibility. Perfectly suited for milling and drilling components made of aluminum, light alloys, PVC, and steel, the Bolero 5 delivers high-quality results across diverse industries, including the aerospace industry and curtain wall manufacturing.

Key Features and Specifications

1. Structural Excellence for High Rigidity

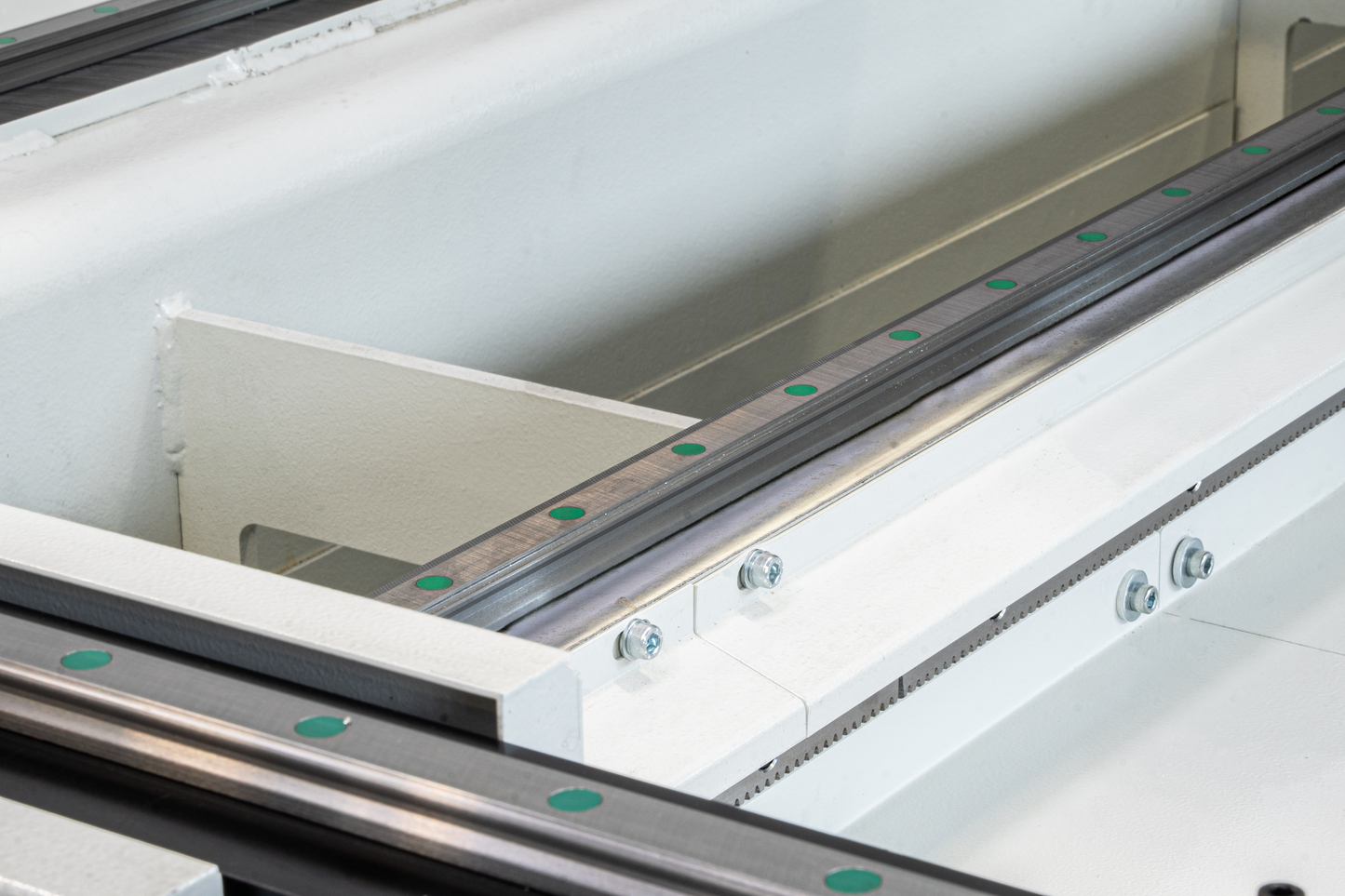

Robust electro-welded steel base with gantry-style assembly ensures machining rigidity and durability.

Designed for heavy-duty work and optimal machining accuracy.

2. Axes Precision and Motion

X-axis stroke: Up to 9,400 mm with a speed of 100 m/min.

Y-axis stroke: 1,300 mm with a speed of 53 m/min.

Z-axis stroke: 670 mm, providing fine-tuned operations for complex geometries.

3. Pivoting Capability

A-axis pivoting angles: ±135° for intricate machining.

C-axis pivoting angles: ±320° for 360-degree flexibility.

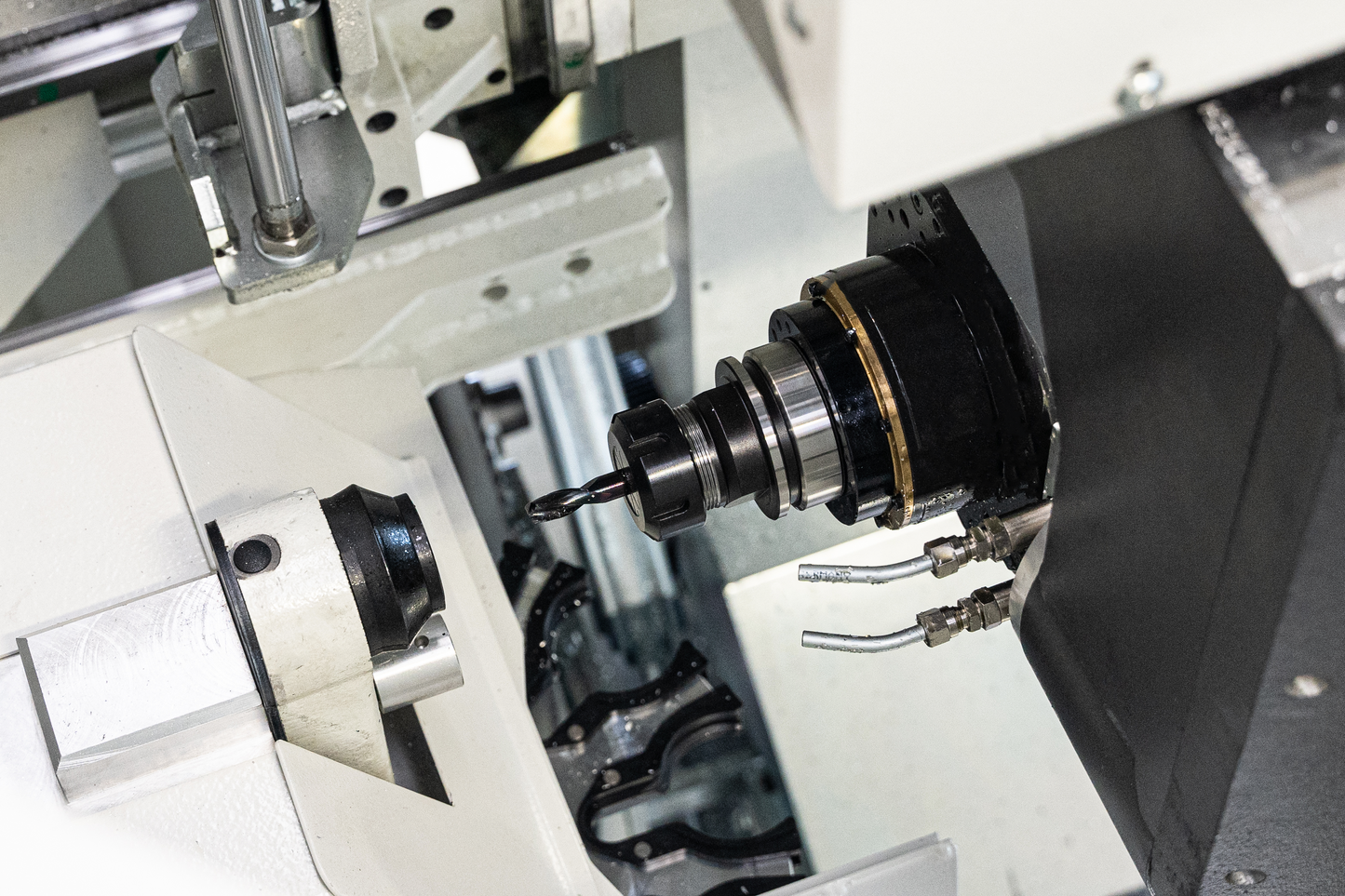

4. Advanced Electrospindle

Power: 15 kW with speeds ranging from 1,000 to 24,000 RPM.

Equipped with high precision ceramic bearings, liquid cooling, and micro-droplet tool lubrication for consistent, reliable performance.

5. Tool Magazine for Enhanced Efficiency

Automatic tool changer with a 12-position carousel, accommodating tools up to 10 kg.

Supports a wide range of tools, ensuring flexibility and production efficiency.

Advanced Capabilities and Optional Upgrades

The Bolero 5 stands out for its versatility and scalability:

Optional length extension for larger projects.

Pendulum machining capabilities for continuous operation.

Add-ons like a touch probe, motorized belt conveyor, and CAMQUIX software license for enhanced control and functionality.

This CNC machining center complies with Industry 4.0 standards and integrates seamlessly into smart manufacturing setups.

Precision Meets Innovation

Built for high-speed, precise operations, the Bolero 5 is the ideal solution for manufacturing needs that demand exceptional machining accuracy and reliability. Its applications extend to processing extruded aluminum, light steel materials, and other components with high rigidity and precision.

Industries Served

Aerospace: Delivers unmatched precision for critical applications.

Construction: Ideal for curtain walls and other architectural elements.

Manufacturing: From prototypes to multiple pieces, the Bolero 5 handles it all.

Specifications at a Glance

X-Axis Stroke: Up to 9,400 mm

Y-Axis Stroke: 1,300 mm

Z-Axis Stroke: 670 mm

Spindle Speed: 1,000 - 24,000 RPM

Tool Magazine: 12 positions + 1

Pivoting Angles: ±135° (A-axis), ±320° (C-axis)

Accuracy: Positioning ± 0.2 mm, Repeatability ± 0.1 mm

Frequently Asked Questions

What is a 5-axis machining center?

A 5-axis machining center like the Bolero 5 allows simultaneous movement along five axes for intricate machining and drilling tasks.

What is it used for?

It's used for creating complex shapes in materials like aluminum, steel, and PVC, especially in aerospace, construction, and manufacturing industries.

Machine Capabilities

The Bolero 5 is engineered to deliver high accuracy and efficiency in machining aluminum, steel, and UPVC profiles. Its advanced 5-axis capability allows for intricate machining operations, including cutting, drilling, and milling on multiple surfaces and planes. This versatility ensures that even the most complex geometries can be handled with ease. The high-speed spindle, combined with an advanced CNC control system, provides precise control over the machining process, resulting in superior finishes and accurate dimensions. Whether you’re working on detailed components or large-scale projects, the Bolero 5 machining center guarantees high accuracy and exceptional performance.

Aerospace Industry Applications

In the aerospace industry, precision and reliability are paramount. The Bolero 5 machining center excels in this domain, making it an ideal choice for producing aircraft components, satellite parts, and other precision-engineered products. Its high accuracy and ability to machine complex shapes and designs meet the stringent requirements of aerospace manufacturing. The machine’s versatility extends to working with a variety of materials, including aluminum, steel, and titanium, providing a comprehensive solution for aerospace manufacturers. With the Bolero 5, you can achieve the exacting standards necessary for critical aerospace applications.

Technical Specifications

The Bolero 5 machining center boasts a range of technical specifications that underscore its high-performance capabilities. The machine’s spindle power is rated at 12 kW, with a maximum speed of 24,000 rpm, ensuring efficient and powerful machining. The X-axis stroke reaches up to 7,000 mm, while the Y-axis stroke is 1,000 mm, and the Z-axis stroke is 550 mm, providing ample range for various machining tasks. The B-axis rotation range is ±185°, and the C-axis rotation range is ±320°, offering extensive flexibility for complex operations. The tool magazine has a capacity of 11 tools, with a swift tool change time of just 3 seconds, enhancing production efficiency and minimizing downtime.

Design and Features

The Bolero 5 is designed with a robust and rigid structure that ensures high machining accuracy and stability. Its gantry-type assembly, along with a moving beam and column design, facilitates smooth and precise movement of the spindle and tooling. The advanced CNC control system, coupled with high-quality servo motors and ball screws, provides meticulous control over the machining process, ensuring consistent and reliable results. The machine’s tool magazine and automatic tool change system enable quick and efficient tool changes, significantly reducing production time and boosting productivity. With its combination of advanced features and solid design, the Bolero 5 stands out as a top-tier machining center for demanding applications.