Gemma

FLEX L: Large Copy Router for Aluminum Machining

FLEX L: Large Copy Router for Aluminum Machining

Couldn't load pickup availability

Large Copy Router for Aluminum Machining: Flex-L Manual Copy Router Precision and Efficiency

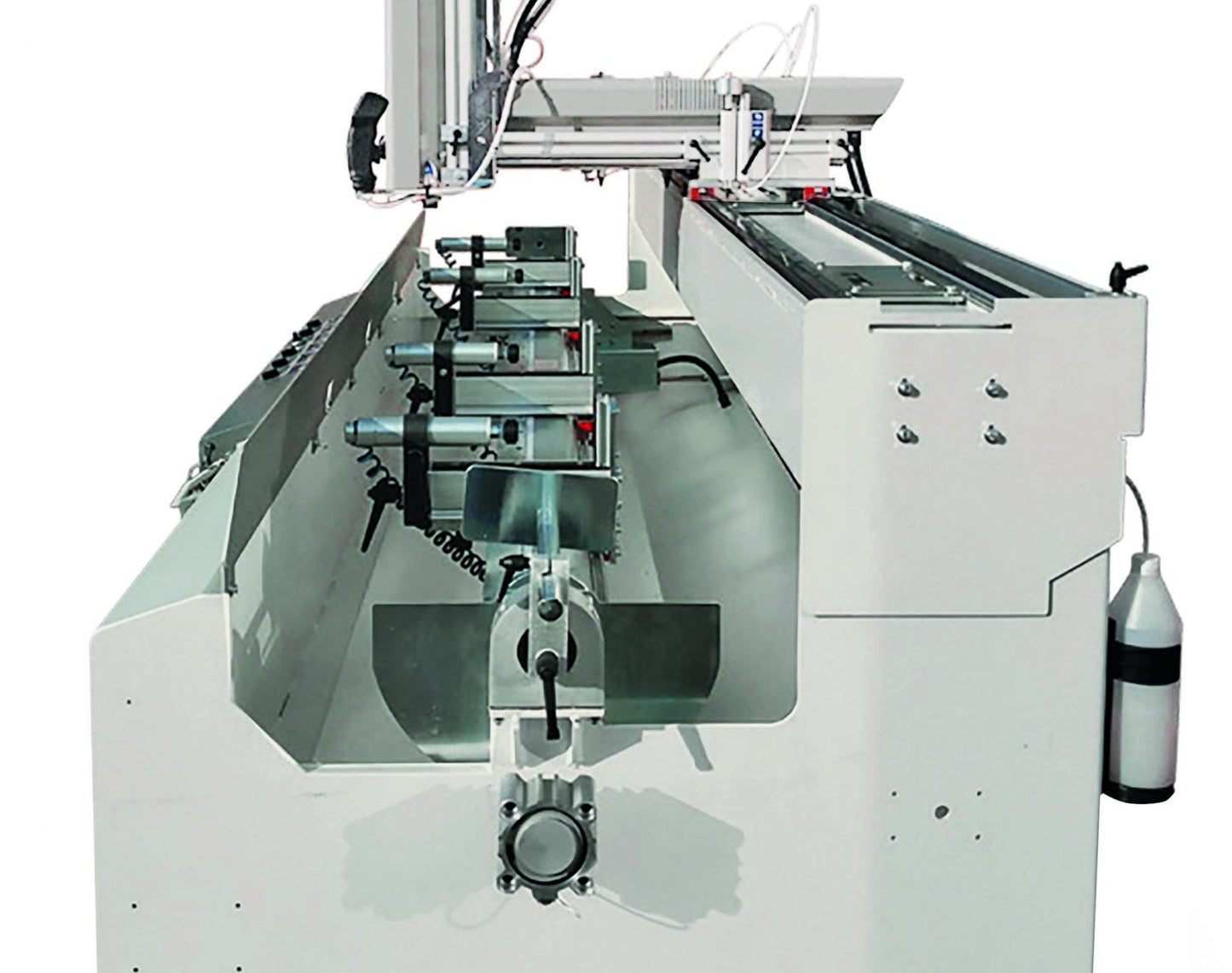

The Flex-L Copy Router is the ultimate solution for professionals in the aluminum machining industry, featuring a state-of-the-art copy router machine. Designed to combine high efficiency, precision, and a compact structure, this manual copy router is your reliable partner for creating accurate holes, grooves, and water slots across a variety of materials, including aluminium, PVC, and steel.

Technical Specifications

| Specification | Details |

|---|---|

| Work Area Dimensions | X-axis: 3,000 mm Y-axis: 400 mm Z-axis: 350 mm |

| Cutting Unit | Cutter Diameter: Ø 8 mm Adjustable Rotation Speed: 2,800–12,000 RPM Cutting Angles: -90°, 0°, +90° |

| Compressed Air Supply | Air Pressure: 7 Bar Air Consumption Per Cycle: 24 Nl |

| Power Requirements | Voltage: 400 V / 50 Hz Motor Power: 1.5 kW |

| Machine Dimensions | 3,700 mm x 1,200 mm x 1,850 mm Weight: 750 kg |

Share

Collapsible content

Key Features and Benefits

- Versatile Machining Capabilities

The Flex-L excels at machining materials like aluminum, inox, and iron with seamless precision. Its large useful scope and adaptability make it a standout for diverse industrial applications, including the production of curtain walls and PVC windows.

- Advanced Cutting Technology

Equipped with a 3-phase electrospindle adjustable between 2,800 and 12,000 RPM, the machine ensures optimized milling speeds for varied materials. A Venturi lubrication system further enhances machining precision by reducing friction.

- User-Friendly Design

This machine features an automatic pivoting worktable (-90° to 90°), a graduated ruler with reference stops, and ergonomic controls, delivering convenient operation achieve and unmatched ease of use.

- Safety Standards Compliance

With integral cutting area protections and CE safety certifications, the Flex-L guarantees a secure and compliant working environment.

- Durable Construction

Built on an electro-welded steel basement, the Flex-L is engineered for longevity and stability under demanding workloads.

Applications

The Flex-L is specifically designed for:

- Copy routing for aluminum and PVC window profiles

- Precision milling with routers for water slots, holes, and grooves

- Industrial-scale production of curtain walls and window frames

Why Choose the Flex-L?

The Flex-L, equipped with a copy router machine, delivers the perfect balance of nice design, robust performance, and convenient operation, making it a valuable asset for improving production efficiency. Its high-precision clamps, customizable settings, and sturdy build ensure optimal results across a variety of tasks, meeting the needs of industries worldwide.

Optional Features

- Lateral stop (1 m)

- Plier and cutter options (Ø 6 mm / 10 mm)

- USA-Canada configuration (UL-CSA compliant)

- Packaging for maritime transport

Discover the Flex-L Advantage

Experience precision, durability, and efficiency like never before with the Flex-L Copy Router. Contact Gemma for more details and a customized solution to your machining needs.