Gemma

KAPPA: The Single Head Miter Saw for Compound Cuts

KAPPA: The Single Head Miter Saw for Compound Cuts

Couldn't load pickup availability

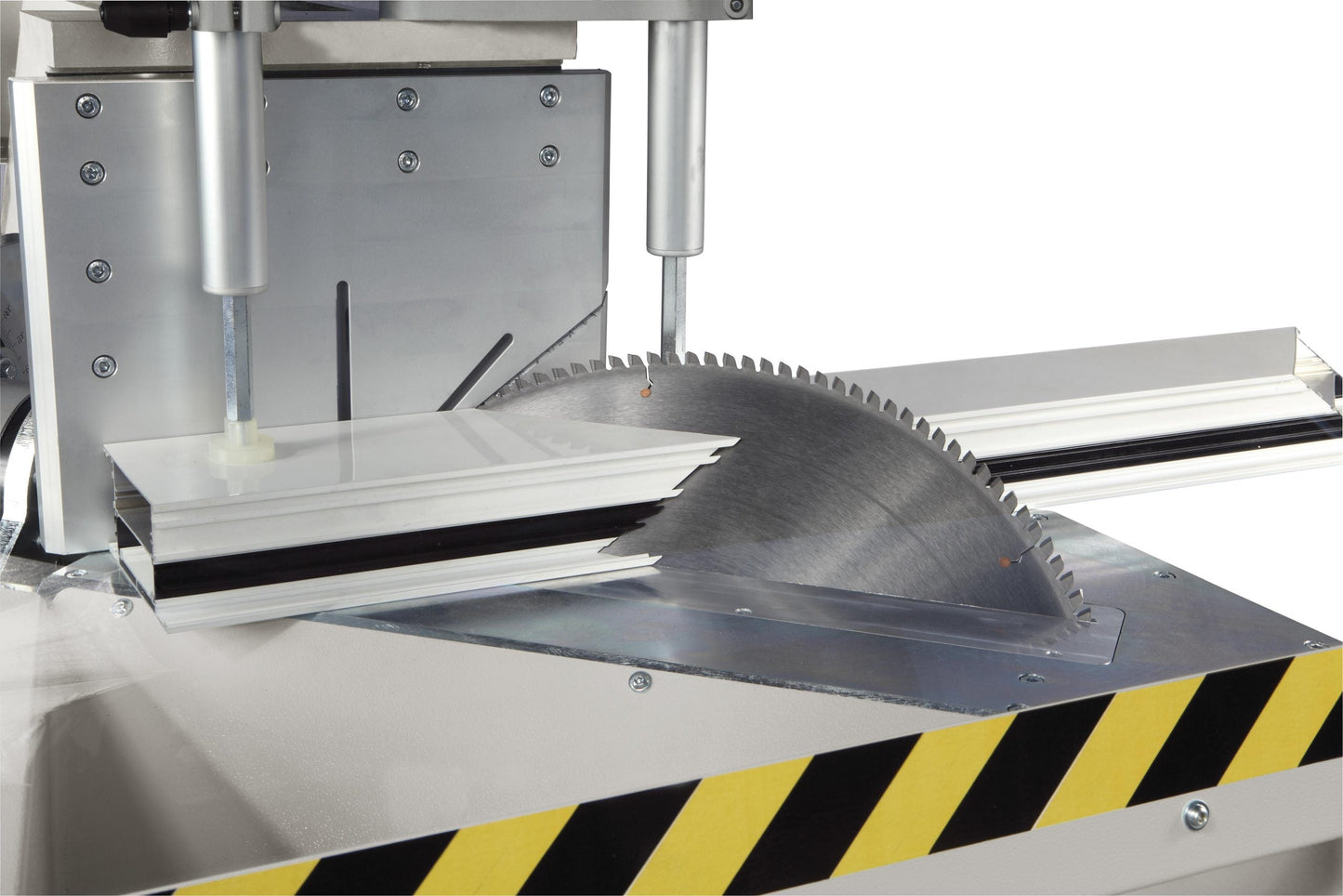

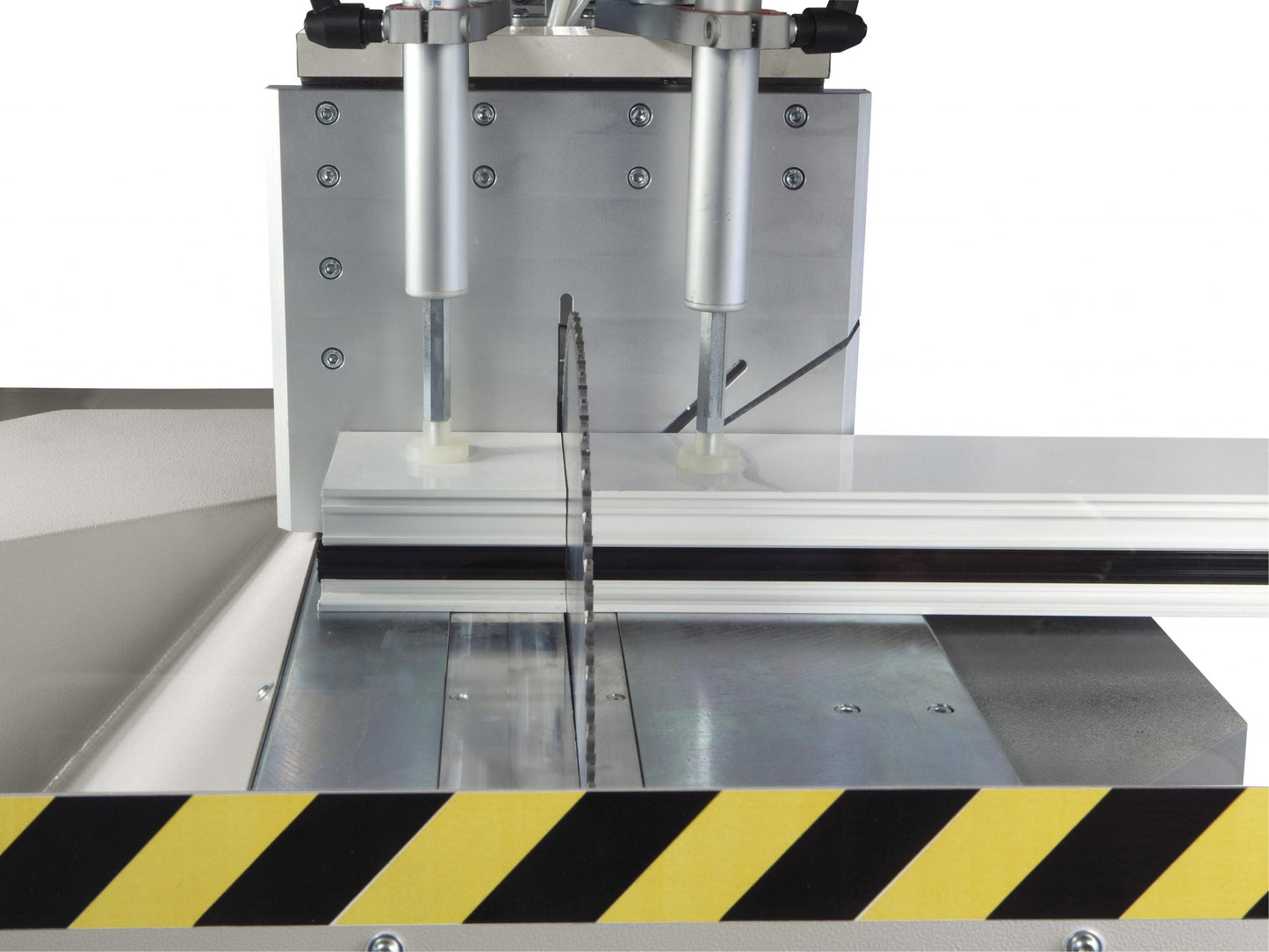

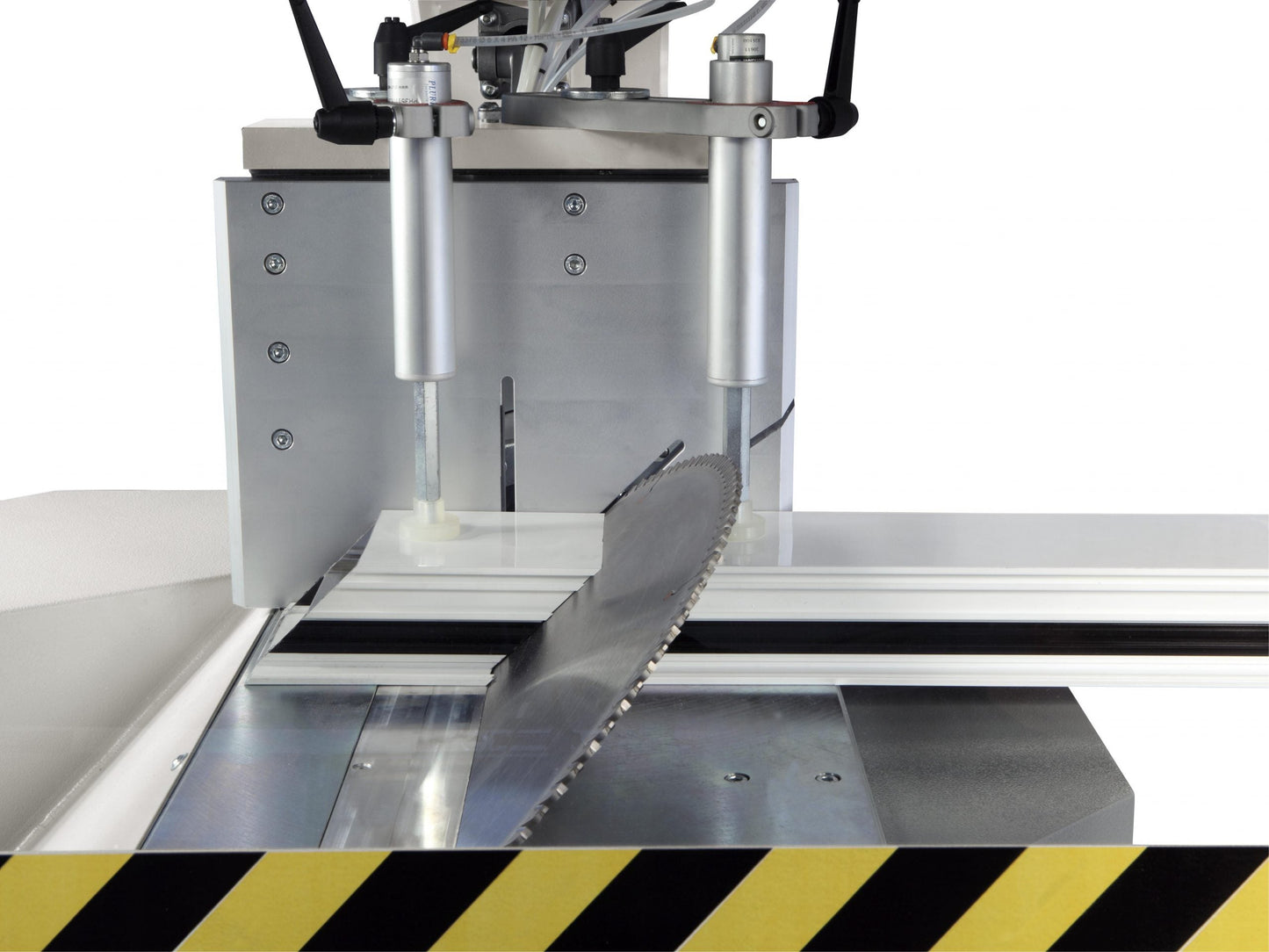

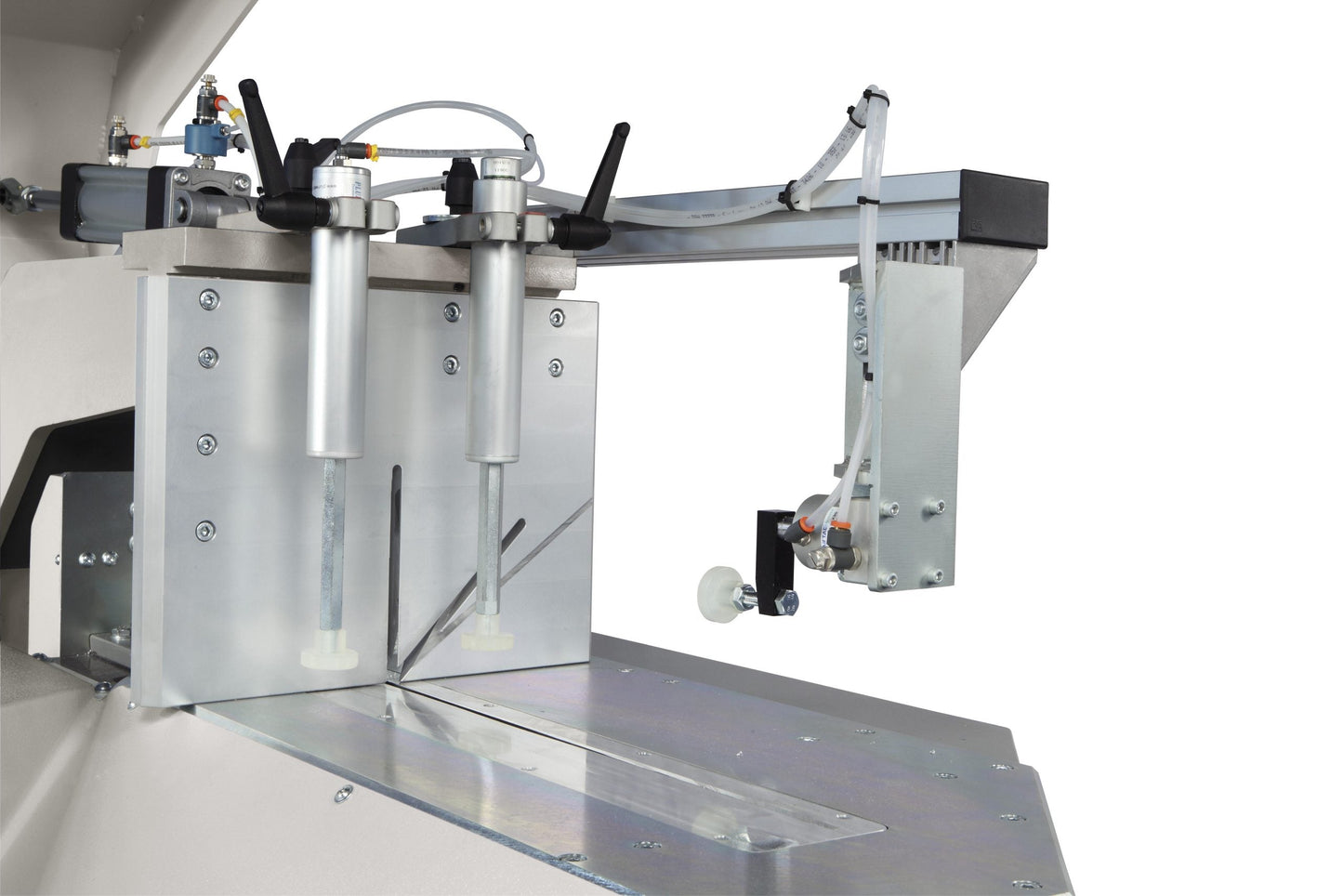

Single-head cutting-off machine with tilting and rotating ascending blade for pyramid cuts. The machine has a ribbed electro-welded steel base and is equipped as standard with 2 vertical pneumatic clamps. Blade diameter is crucial for the machine's cutting capabilities, with larger diameters enabling longer cuts. Cutting unit motor power 3 kW at 2.800 rpm with standard equipment of widia blade diam. 600mm.

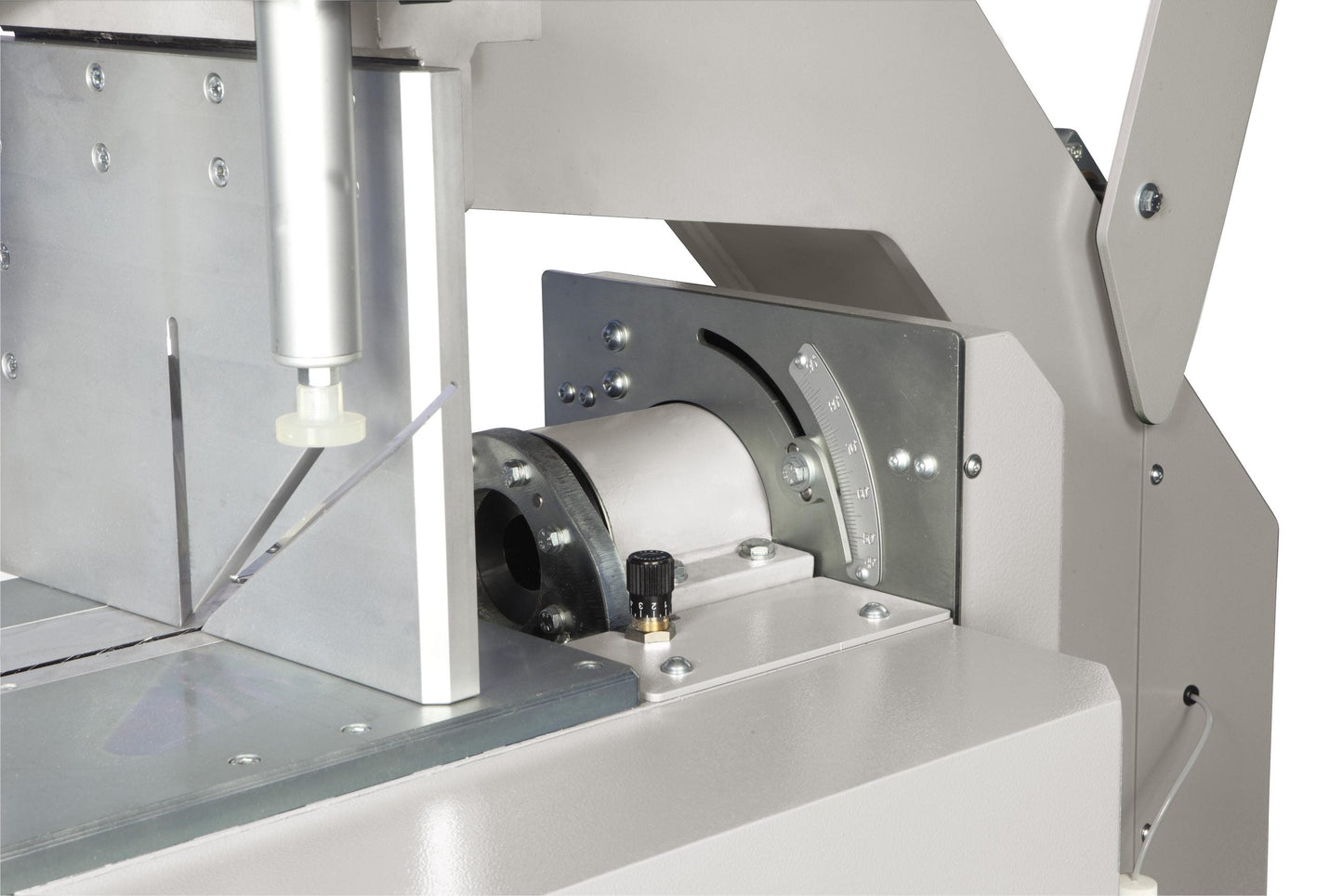

Nebulised cutting lubrication (Venturi system). Tiltable plane with mechanical stops for quick selection of cutting angles (45°/90°). Rotation angles from 40° to 157,5°. Protractor and digital display for locating cutting angles on a rotating plane. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Precision Meets Performance

The Kappa single-head cutting-off machine offers unparalleled precision and versatility for compound cuts. Engineered with advanced features, it can perform beveled cuts simultaneously, making it the perfect solution for professionals seeking accurate and efficient cutting in both industrial and workshop settings.

Technical Specifications

| Specification | Value |

| Power Supply | 400 V / 50 Hz |

| Motor Power | 3 kW |

| Blade Specifications | 600 mm diameter, 30 mm shaft diameter. Similar to circular saws, this blade is designed for cutting various materials like wood, stone, brick, or plastic. |

| Pivoting Angles | 40° to 157.5° |

| Tilting Angles | 90° to 135° |

| Compressed Air Requirements | 7 Bar, 22 Nl per cycle |

Share

KAPPA Single-Head Cutting-Off Machine for Compound Cuts

What is a Miter Saw?

A miter saw is a specialized power tool designed for making precise angled cuts in various materials, including wood, metal, and plastic. It typically consists of a circular saw blade mounted on a pivoting arm, allowing for adjustments to precise angles across multiple axes. This versatility makes miter saws indispensable for woodworking tasks such as picture framing, crown molding, and furniture making. Whether you’re crafting intricate designs or performing routine cuts, a miter saw ensures accuracy and efficiency, making it a staple in both professional workshops and DIY settings.

Types of Miter Saws

There are several types of miter saws available, each designed for specific tasks and applications:

- Compound Miter Saws: These saws can make both miter cuts and bevel cuts, allowing for precise angled cuts in multiple directions. They are ideal for complex woodworking projects that require angled cuts along both the width and thickness of the material.

- Sliding Compound Miter Saws: Combining the features of compound miter saws with a sliding carriage, these saws allow for longer cuts and increased versatility. They are perfect for cutting wider materials without compromising on precision.

- Cordless Miter Saws: Powered by rechargeable batteries, cordless miter saws offer increased portability and convenience, making them suitable for job sites where power outlets may not be readily available.

- Single Bevel Miter Saws: These saws can make miter cuts in one direction and bevel cuts in one direction, providing a straightforward solution for basic angled cuts.

- Double Bevel Miter Saws: Capable of making bevel cuts in both directions, these saws eliminate the need to flip the workpiece, saving time and ensuring consistent accuracy.

Key Features

- Versatile Cutting Angles: The Kappa is designed to handle a wide range of compound cuts, with head tilting and pivoting capabilities. Achieve bevel cuts, miter cuts, and angled cuts effortlessly.

- Robust Construction: Built on an electro-welded steel base, the Kappa ensures stability and durability for long-term heavy-duty use.

- High-Performance Blade: Equipped with a 600 mm widia blade and an oleopneumatic blade output management system, it delivers precise cuts at speeds of up to 2,800 rpm.

- User-Friendly Design: Features such as digital angle displays, mechanical stops for quick angle selections, and pneumatic clamps make operation seamless.

- Correct Miter Saw Blades: Emphasizes the importance of using the correct miter saw blades for precise and efficient cutting. Ensure the teeth face downwards and choose blades that match your specific saw's requirements for safety and efficiency.

Cutting Capacity

The Kappa excels in delivering precise cuts for various materials:

- At 90°: Up to 200x200 mm or 400x150 mm.

- At 45°: Up to 170x170 mm or 310x100 mm. This makes it ideal for processing wood, aluminum, and non-ferrous metals.

The Kappa machine can also perform a bevel cut, which involves tilting the saw blade to create angled cuts. This feature is essential for precise carpentry tasks like installing trim and allows for complex joinery in woodworking projects.

Advanced Safety and Compliance

The Kappa complies with CE safety regulations, featuring automatic cutting area protections and an IP55-rated electrical cabinet. These features ensure operator safety during heavy-duty operations.

Optional Add-Ons

- Microdrop lubrication system

- Spare 600 mm widia blade

- Additional pneumatic clamps

- Pivoting stops at 45°, 90°, and 135°

- USA-Canada setup (UL-CSA standards)

Applications

The Kappa’s precise cutting capabilities make it ideal for:

- Crown moulding

- Picture frames

- Industrial aluminum profiles

- Wood and plastic components

Compared to radial arm saws, which are versatile machines primarily utilized for cross-cutting, the Kappa machine offers enhanced precision and versatility for a wider range of applications.

Choosing the Right Miter Saw for Your Project

When choosing a miter saw for your project, consider the following factors:

- Blade Size: Larger blades can make longer cuts, but may be more difficult to maneuver. Choose a blade size that matches the scale of your projects.

- Motor Power: More powerful motors can handle thicker materials and make faster cuts. Ensure the motor power is sufficient for the types of materials you will be cutting.

- Bevel Capacity: If you need to make bevel cuts, look for a saw with a high bevel capacity to accommodate a range of angles.

- Miter Capacity: For precise miter cuts, select a saw with a high miter capacity to achieve the desired angles accurately.

- Cordless or Corded: Consider the convenience of a cordless saw for mobility versus the reliability of a corded saw for continuous power.

KAPPA Miter Saw Accessories and Stands

KAPPA offers a range of accessories and stands to enhance the functionality and safety of their miter saws:

- Miter Saw Stands: These stands provide a stable and adjustable platform for your miter saw, allowing for precise cuts and increased safety. They are designed to support the saw and the workpiece, ensuring stability during operation.

- Laser Guides: Laser guides project a beam of light onto the workpiece, helping to align the blade and make accurate cuts. This feature is particularly useful for achieving precise cuts without the need for manual measurements.

- Dust Collection Systems: These systems help to reduce dust and debris, making the cutting process cleaner and safer. Effective dust collection not only improves visibility but also prolongs the life of the saw by preventing dust buildup.

Troubleshooting Common Issues

Common issues with miter saws include:

- Inaccurate Cuts: If your cuts are not accurate, check the blade for damage or wear, and ensure that the saw is properly calibrated. Regular maintenance and calibration are key to maintaining precision.

- Binding or Kickback: Binding or kickback can occur if the blade is not properly aligned or if the workpiece is not securely clamped. Always check the alignment and secure the workpiece before cutting.

- Motor Overheating: Overheating can be a sign of poor ventilation or overuse. Check the saw’s ventilation system and ensure it is properly maintained to prevent overheating.

KAPPA Miter Saw Warranty and Support

Gemma offers a comprehensive warranty and support program for their miter saws, ensuring peace of mind for users:

- 1 -Year Warranty: Gemma provides a 1-year warranty on their miter saws, covering defects in materials and workmanship. This warranty ensures that your investment is protected.

- Customer Support: Dedicated customer support is available via phone and email, along with online resources and tutorials to assist with any issues or questions.

- Repair and Maintenance: Gemma offers repair and maintenance services, including blade replacement, to keep your miter saw in optimal condition.

By choosing Gemma, you are investing in a reliable and high-performance miter saw, backed by robust support and warranty services.

Why Choose the Kappa?

The Kappa single-head cutting-off machine stands out for its innovative design and superior performance. Its ability to handle compound cuts with precision and efficiency makes it a top choice for professionals in woodworking, metalworking, and industrial manufacturing.

FAQs

What is the difference between standard miter saws and compound miter saws?

A compound miter saw, like the Kappa, allows for both miter cuts (angled cuts) and bevel cuts (angled cuts along the thickness of the material), enabling complex compound cuts for advanced applications.

What type of cutting should not be done on the Kappa?

Avoid using the Kappa for cuts on extremely hard materials such as concrete or ferrous metals unless otherwise specified. For such heavy-duty applications, consider using concrete saws, which are equipped with diamond blades and are specifically designed for cutting tough materials like concrete, asphalt, and pavement.

What are the four types of cuts that can be made with a compound miter saw?

The Kappa enables miter cuts, bevel cuts, compound cuts (combination of miter and bevel cuts), and straight cuts.

What is the correct blade diameter for the Kappa?

The Kappa uses a 600 mm widia blade for precise and durable performance across various materials.