Gemma

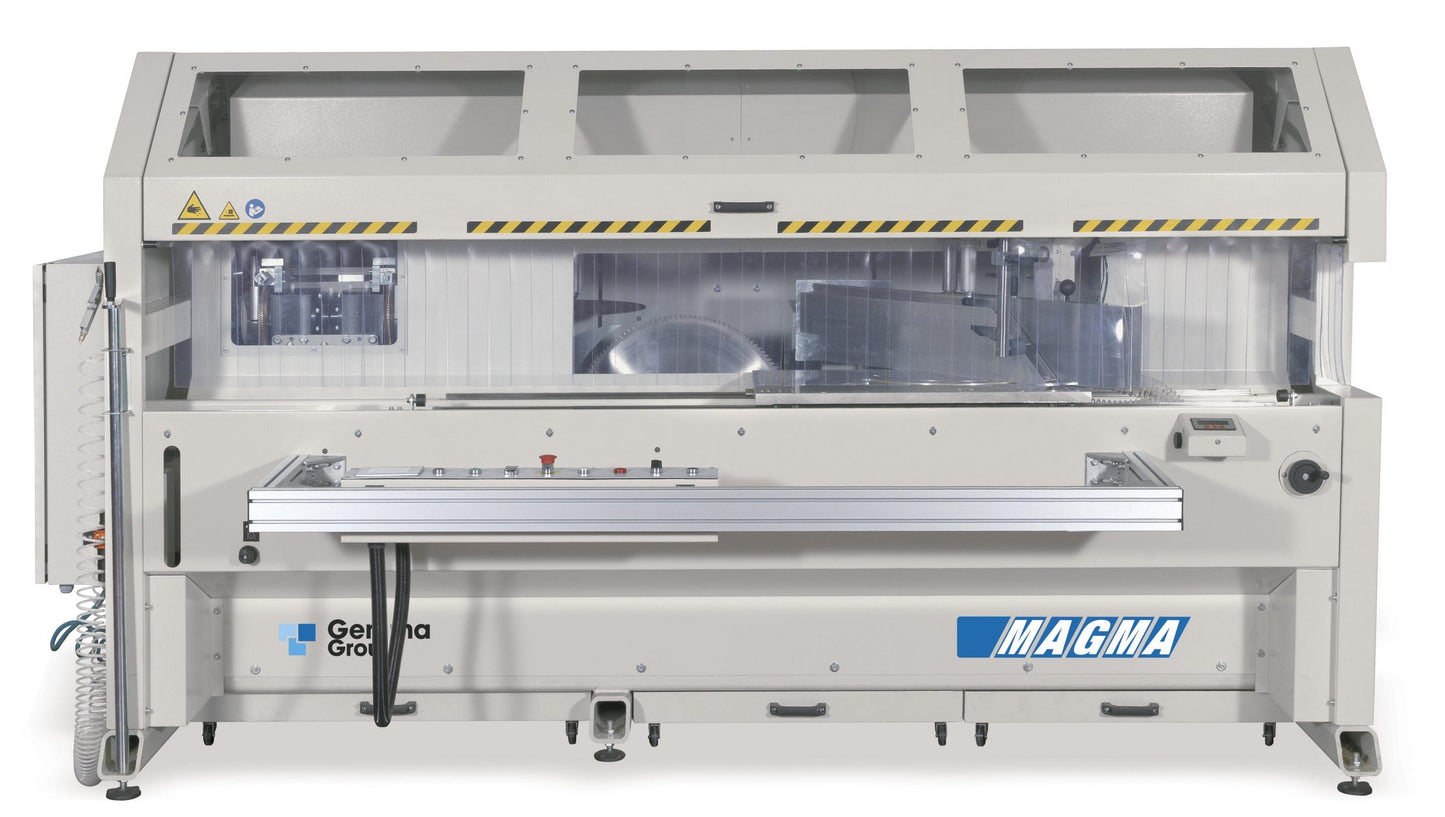

MAGMA Double-blade orthogonal end-cutting machine for aluminum profiles

MAGMA Double-blade orthogonal end-cutting machine for aluminum profiles

Couldn't load pickup availability

Description of the End Milling Machine for Aluminum Profiles

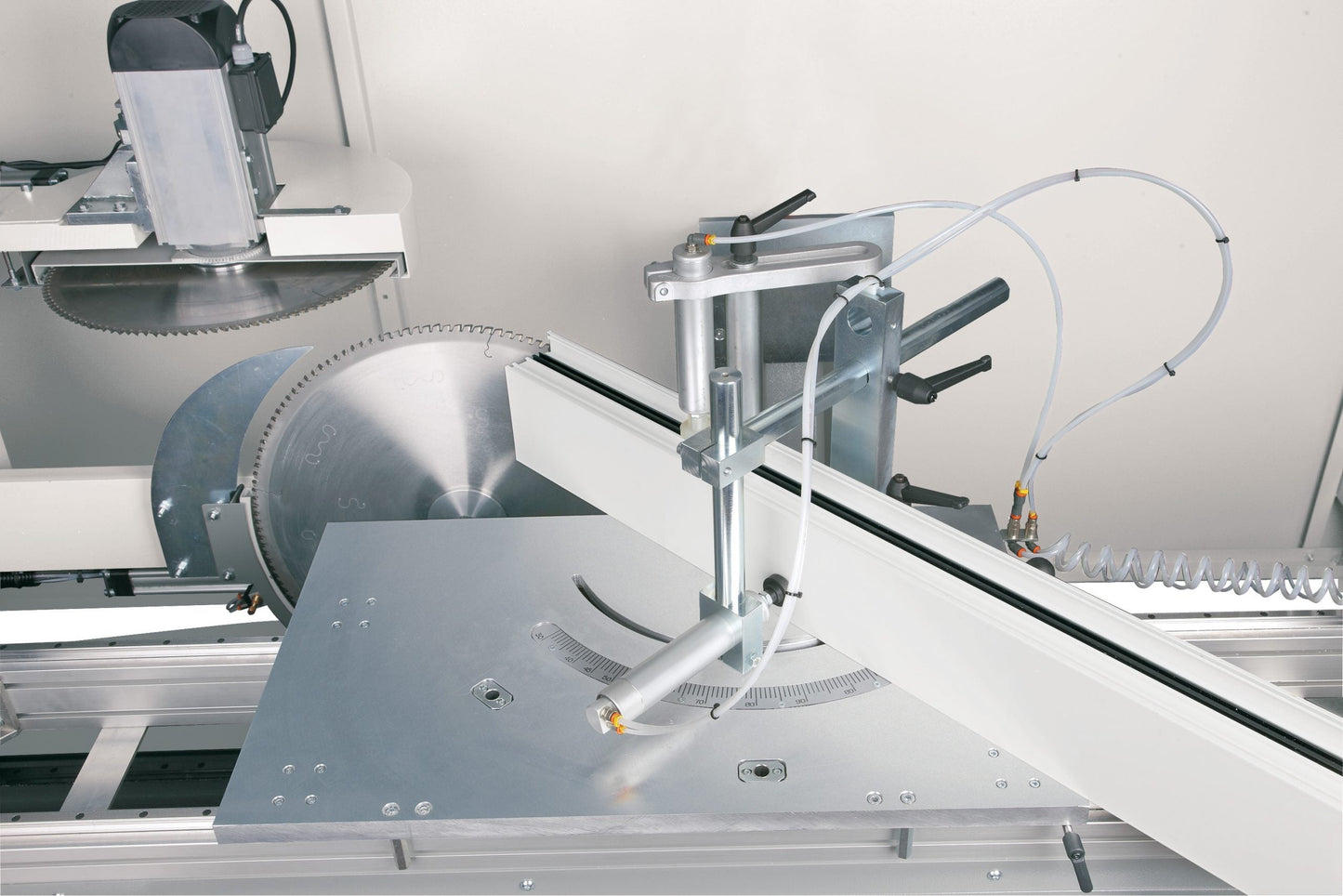

Two-blade orthogonal end-cutting machine designed for processing aluminium profiles. Machine equipped with a ribbed electro-welded steel base, equipped with a vertical and horizontal profile clamping system. Profile support table sliding on linear guides, equipped with a tilting square. Cutting units controlled by a 3 kW motor at 2,800 rpm, equipped as standard with two blades: diam. 600 for vertical unit and diam. 500 for horizontal unit. Cutting unit adjustable in height, depth and inclination with mechanical stops for quick selection of 45° / 90° /135° angles. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Unleash Precision and Efficiency with the Magma End-Milling Machine

The Magma End-Milling Machine, designed for superior performance, is an indispensable tool for manufacturers and suppliers working with aluminum and PVC profiles. Combining innovative features and robust construction, this machine ensures precise milling for a variety of aluminum profiles, making it a reliable choice for professionals due to its versatility in processing different shapes and sizes.

Key Features and Benefits

Exceptional Build Quality

- Electro-welded steel structure: Ensures stability and durability for long-term usage.

- Sliding support table: Facilitates smooth operation with linear guide systems.

High-Precision Cutting Capabilities

- Dual widia blades with orthogonal movement for accurate trimming and milling.

- Adjustable depth stops and tilting squares for quick setup of 45°, 90°, and 135° angles.

- Max cutting depth: Up to 235 mm, adaptable for horizontal and vertical profiles.

Efficient Operation

- Venturi lubrication system: Guarantees optimal cutting conditions and extends blade life.

- Cutting process: The machine carries out various milling operations automatically and accurately, with a maximum speed of 6 m/min to enhance productivity.

- Compressed air system: Consumes just 40 Nl per cycle for high efficiency.

Versatile Applications

Processes a variety of aluminum and PVC profiles with ease, showcasing its ability to efficiently process aluminum profiles of different shapes and sizes with high precision.

Ideal for manufacturers specializing in profile milling and end milling.

Safety and Compliance

- Fully protected cutting area with automatic opening and closing mechanisms.

- Designed to meet CE safety standards, with optional UL-CSA setup for USA and Canada.

Share

Magma Double-blade orthogonal end-cutting machine for aluminum profiles

Overview of End Milling Machines

End milling machines are versatile tools used for processing various materials, including aluminum, PVC, and wood. These machines are designed to perform precise end milling operations, creating accurate joints and finishes in workpieces. End milling machines are essential in industries such as construction, furniture, and window and door manufacturing, where high-quality profiles are required. With their sturdy construction and advanced components, end milling machines ensure efficient and reliable operation, making them a crucial part of modern manufacturing processes.

Technical Specifications

Blade Diameter: 500 mm or 600 mm

Motor Power: 3 kW

Cutting Speed: 2,850 rpm

Max Cutting Depth: 235 mm (90°, 45°, 30°)

Compressed Air: 7 Bar (40 Nl/cycle)

Machine Dimensions: 3,300 x 1,500 x 1,800 mm

Weight: 1,200 kg

Machine Efficiency and Maintenance

End milling machines are engineered for high efficiency, with features such as automatic feeding, quick-change cutter stacks, and advanced CNC systems. These machines are designed to minimize downtime and maximize productivity, allowing for fast and precise processing of various profiles. Regular maintenance is essential to ensure optimal performance, and most end milling machines are designed with easy-to-clean components and straightforward maintenance procedures. By investing in a high-quality end milling machine and following proper maintenance procedures, manufacturers can enjoy improved production rates, consistent quality, and reduced operational costs.

Choosing the Right Machine

Selecting the right end milling machine involves considering specific needs and requirements. Factors such as machine capacity, complexity of tasks, and compatibility with existing systems are crucial in making an informed decision. Prospective buyers should explore a wide selection of machines, considering factors such as price, angles, and processing capabilities. It is also essential to consider the machine’s main feature, such as automatic feeding, air consumption, and milling efficiency. By choosing the right end milling machine, manufacturers can enhance their service offerings, provide bespoke solutions, and improve their overall competitiveness in the market.

Why Choose the Magma End-Milling Machine?

Engineered for precision, efficiency, and versatility, the Magma End-Milling Machine is the ultimate choice for processing aluminum and PVC profiles. Whether you're crafting unique angles or meeting high-volume demands, this machine adapts to your needs with quick-change settings and superior accuracy. Its durable design ensures reliability, while optional configurations meet international standards.

FAQs

What end mill is best for aluminum?

The Magma End-Milling Machine uses dual widia blades, optimized for high-speed aluminum processing.

What is the cutting speed for milling aluminum?

The machine operates at up to 2,850 rpm, ensuring clean and precise cuts.

What type of cutter is used for milling aluminum?

Widia blades with adjustable tilting angles (30° to 90°) are ideal for detailed profile milling.

What is a profile milling cutter?

It is a specialized cutter designed to shape and mill profiles with precision, crucial for achieving exact dimensions and finishes.