Gemma

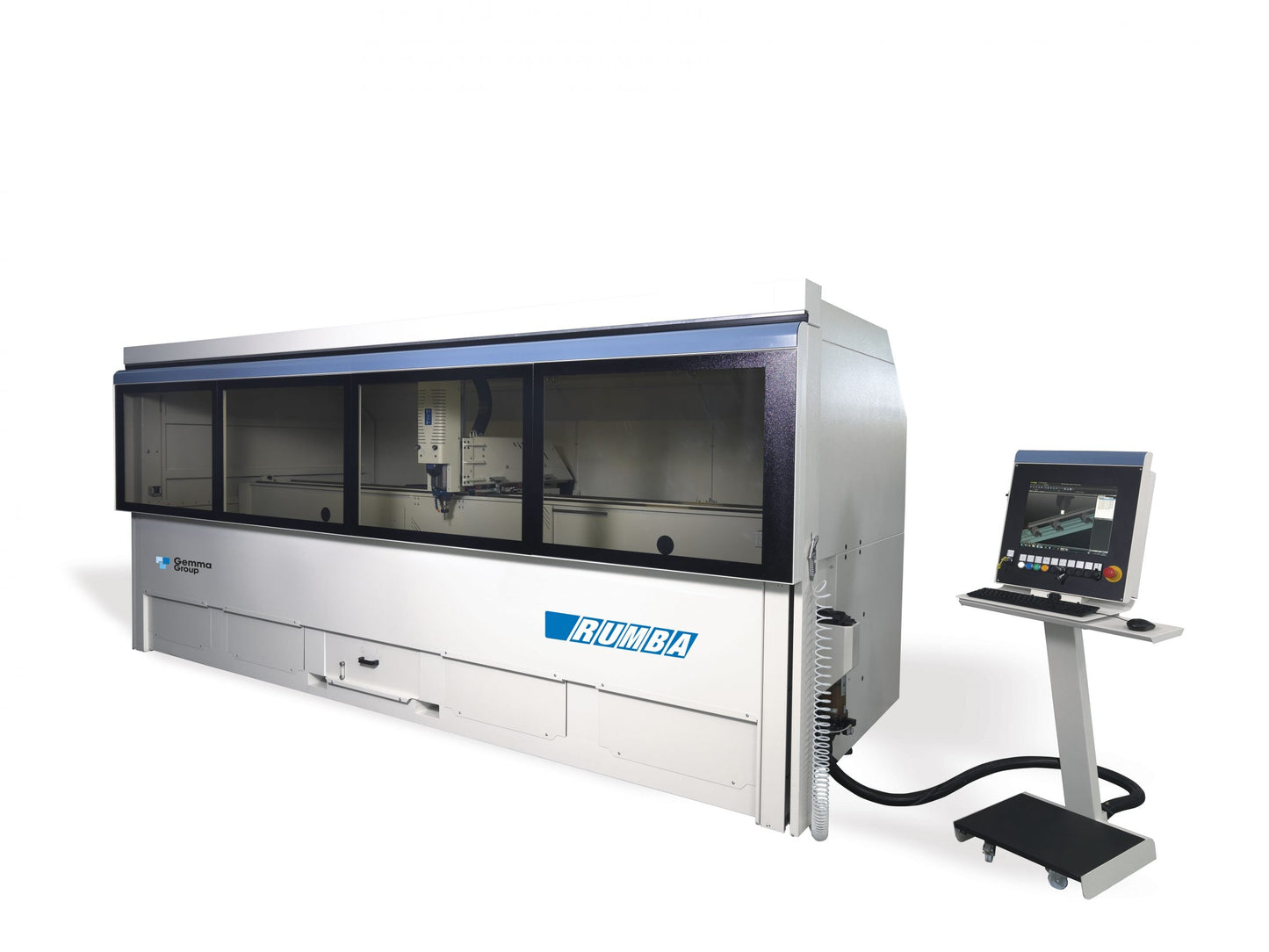

RUMBA

RUMBA

Couldn't load pickup availability

RUMBA: The 4 Axis CNC Machining Center for Aluminum, Steel and PVC

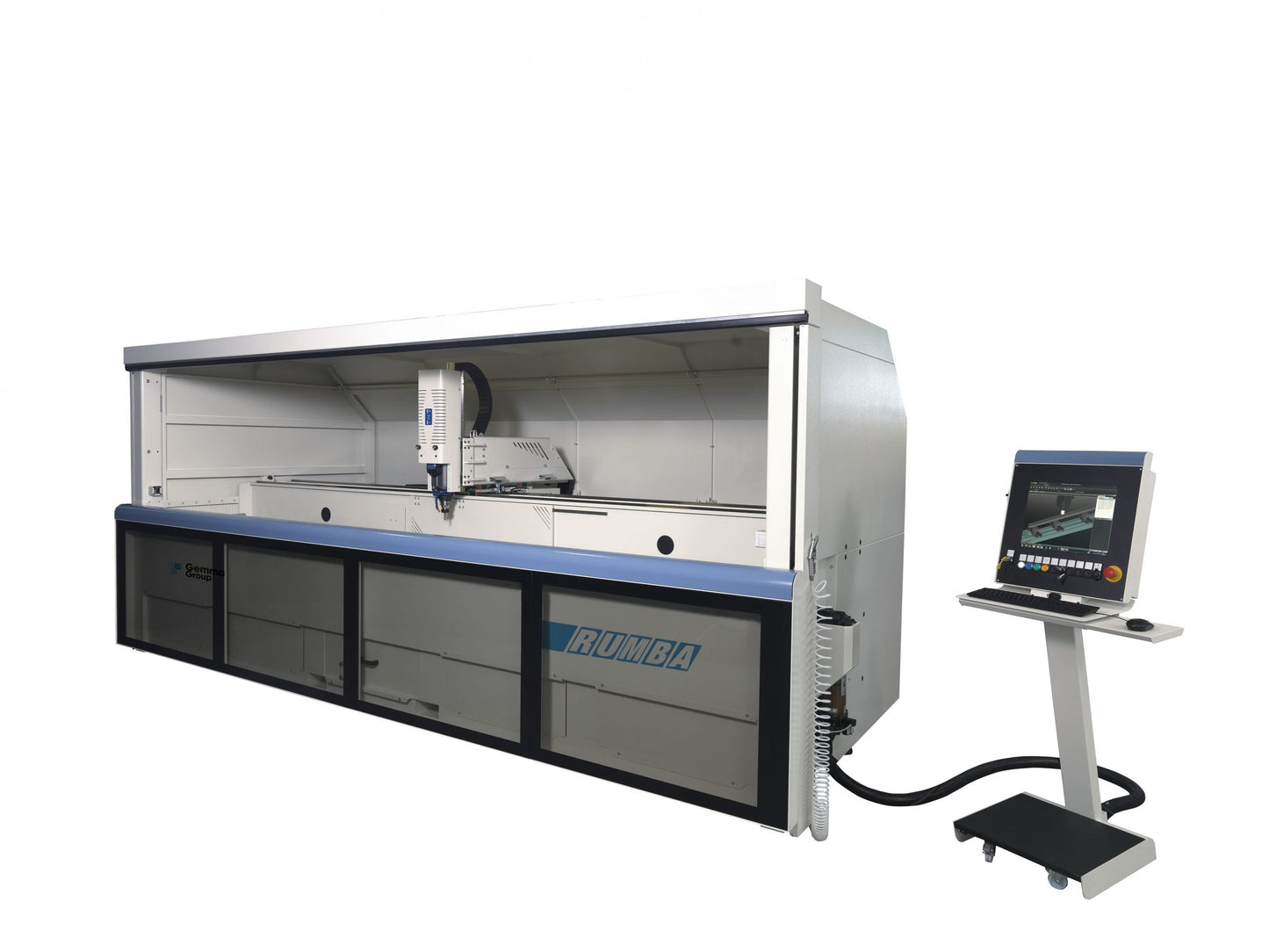

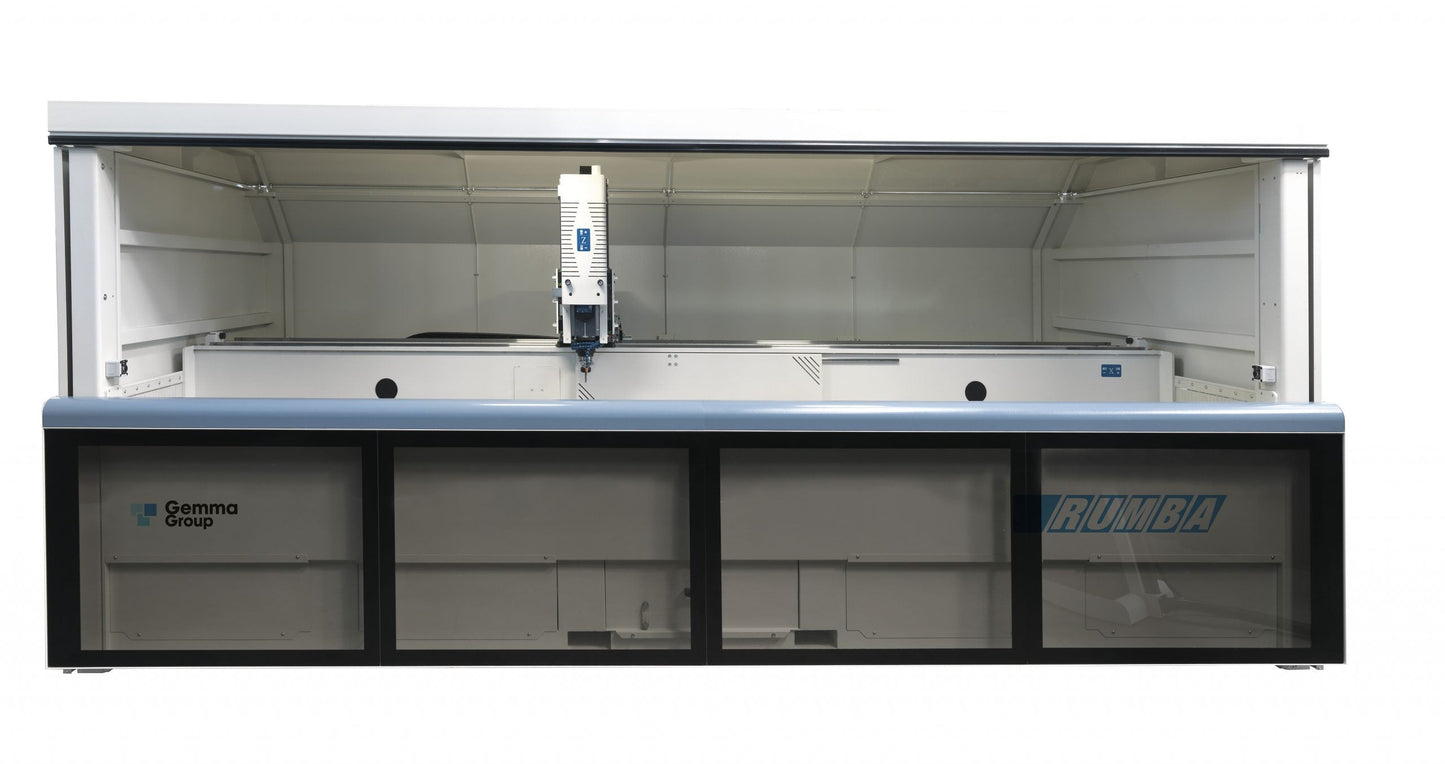

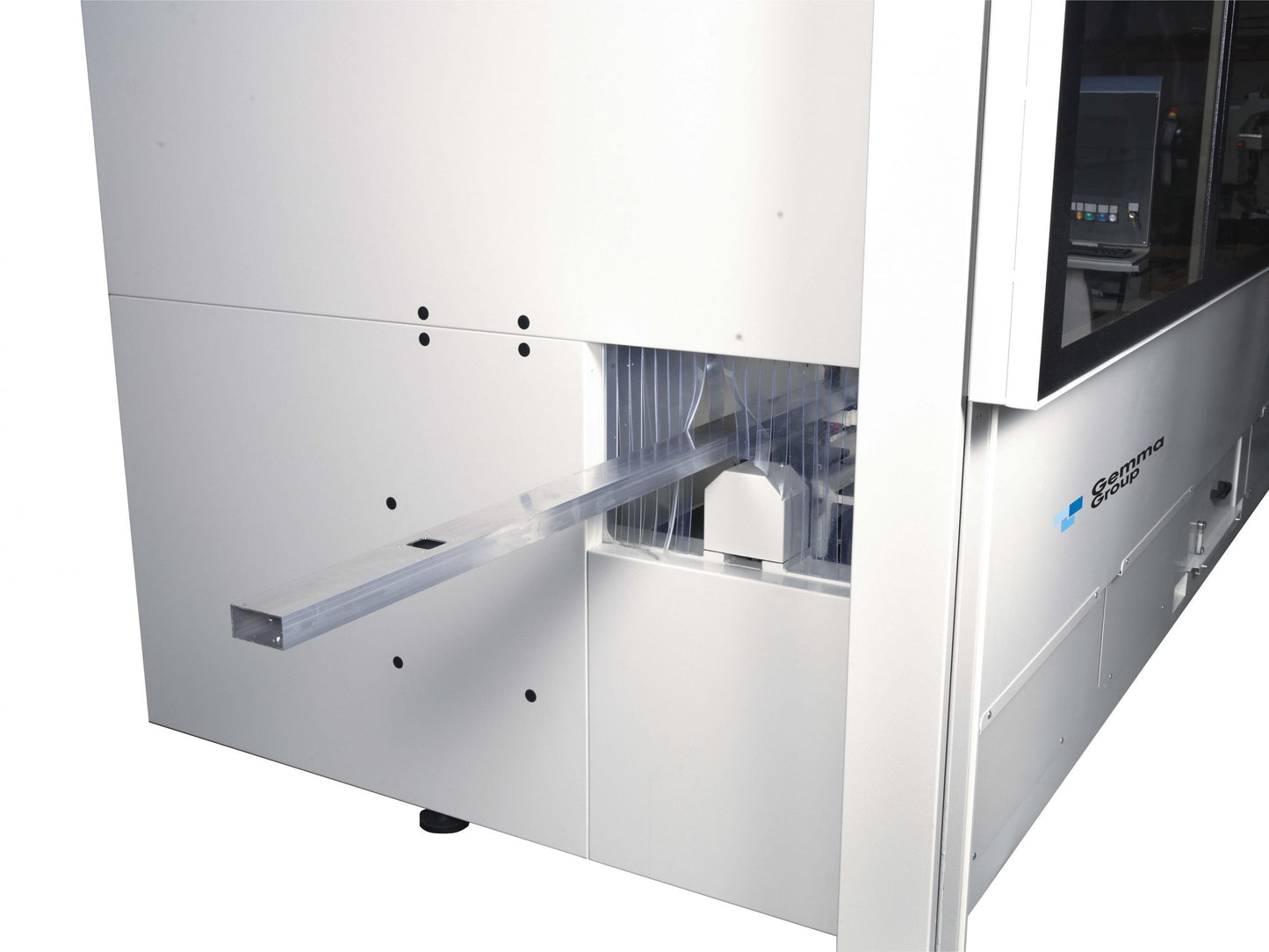

Machining center with 4 NC-controlled axes for machining aluminum, steel, light alloy and PVC components on 4 sides. The machine has a strongly ribbed base in electro-welded steel with a rotating beam and mobile upright. Thanks to its sturdiness and stability, it guarantees high quality workmanship and reliability over time.

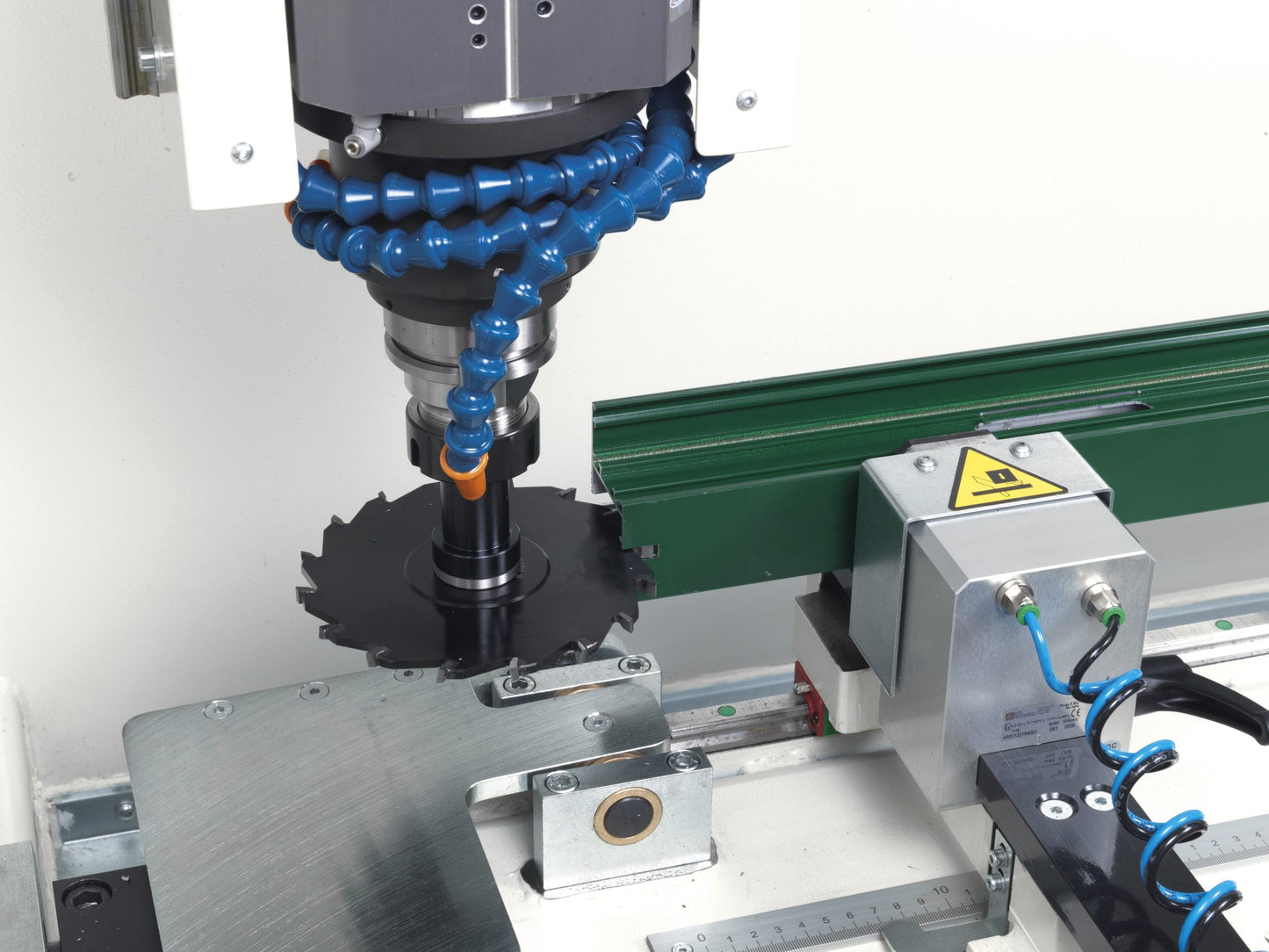

The operating group consists of an inverter-controlled 4 kW electrospindle at 24.000 rpm and is equipped with an ISO30 tool attachment to perform machining combining high finish and high precision. Rumba it is equipped with an automatic tool change device with a 10-position magazine. The work table has rotation controlled by NC and is equipped as standard with 4 double action pneumatic vices. The stroke of the X axis is 3.000 mm (optional extension to 4.000 mm), while that of the Y axis is 400 mm.

It is possible to perform machining on longer pieces than the X-stroke. The operator interface is on PC-Windows with a 17” color screen. The machine is equipped as standard with safety and protection devices in compliance with CE regulations.

Share

RUMBA: The 4 Axis CNC Machining Center for Aluminum, Steel and PVC

CNC Machining Centers

CNC machining centers are the backbone of modern manufacturing, designed to perform a multitude of tasks such as cutting, milling, and drilling with unparalleled precision. These advanced machines are engineered to handle a variety of materials, including aluminum profiles, PVC profiles, light alloys, and steel profiles, making them indispensable in industries ranging from aerospace to construction.

Equipped with state-of-the-art technology, CNC machining centers enable precise and efficient processing of profiles. Their robust construction and sophisticated control systems ensure that each operation is executed with the highest level of accuracy. Whether it’s intricate end milling or complex drilling, these machines deliver consistent results, enhancing productivity and reducing lead times.

The versatility of CNC machining centers lies in their ability to adapt to different materials and machining requirements. With features like automatic tool changers, pneumatic clamps, and advanced axis movements, they offer a comprehensive solution for various machining tasks. This adaptability not only improves operational efficiency but also allows businesses to meet diverse production demands with ease.

In essence, CNC machining centers are a testament to the advancements in manufacturing technology, providing the tools necessary to achieve precision and efficiency in processing aluminum profiles, PVC profiles, light alloys, and steel profiles. Their integration into modern machining operations is a strategic move towards optimizing performance and achieving superior output quality.

Rumba 4-Axis CNC Machining Center: Precision Machining for Aluminum and PVC

The Rumba 4-axis CNC profile machining center is a high-performance solution designed for professionals who demand precision and versatility in processing aluminum profiles, PVC profiles, light alloys, and steel profiles. Its robust design, advanced features, and reliable performance make it an essential tool for modern machining operations.

Versatility Meets Durability

Built with a heavy-duty electro-welded steel base, the Rumba ensures stability and precision in every operation. Its rotating beam and mobile column allow for processing materials of different sizes, which enables machining for complex operations such as end milling, drilling, and machining. This machine excels in performing drilling and milling operations with the accuracy required in industries ranging from construction to aerospace.

Key Features

Advanced Structure:

- Constructed with a heavily ribbed electro-welded steel frame for superior strength and long-term reliability.

- The rotating beam supports angles from -90° to +90° for multi-directional machining, enabling complex operations with ease.

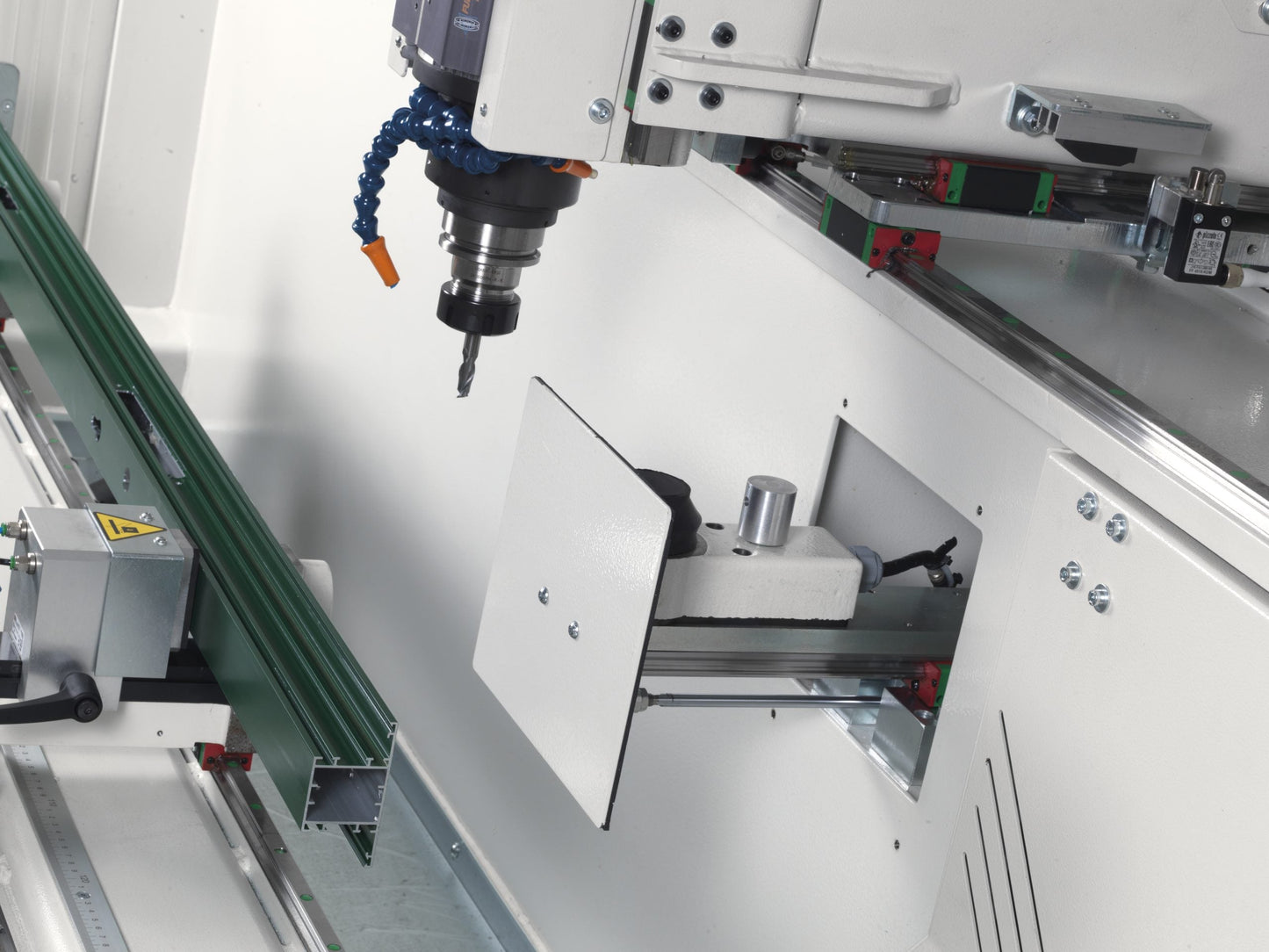

Electrospindle for Precision:

- A powerful 4 kW motor ensures consistent performance.

- Operates at speeds from 1,000 to 24,000 rpm, making it ideal for end milling and drilling aluminum profiles.

- Features ISO30 taper for enhanced compatibility and flexibility in tool use.

Automatic Tool Changer:

- Equipped with 10 tool holders, allowing smooth and efficient transitions between tools during machining.

- Ensures optimal performance for tasks involving process aluminum profiles and PVC.

Pneumatic Clamps:

- Includes four double-action pneumatic clamps to securely hold materials during machining, increasing precision and reducing material waste.

- Supports various materials including steel, aluminum, PVC, and light alloys.

Precise Axis Movements:

- X-axis stroke options: 3,000 mm (standard) or 4,000 mm (optional).

- Y-axis stroke: 475 mm; Z-axis stroke: 400 mm.

- Positioning accuracy: ±0.2 mm; repeatability: ±0.1 mm.

- Operates with brushless motors for precise, high-speed movements on all axes.

User-Friendly Control and Compliance

The Rumba simplifies complex machining with its industrial PC interface, ensuring an efficient and smooth workflow:

- Operates on PC-Windows with Wi-Fi connectivity and teleassistance, making troubleshooting and updates hassle-free.

- Features the OSAI control system with HICAM 2 operator interface for uploading machining programs, listing tasks, and visualizing workpiece lead times.

- Fully enclosed in a protective cabin, the Rumba complies with CE safety regulations, prioritizing operator safety during machining operations.

Optimized for Performance

The Rumba is engineered to handle demanding operations with ease:

- Machining Area: Designed to accommodate different sizes of workpieces, making it versatile for various industries.

- Processing Speed: Achieves speeds of up to 100 m/min on the X-axis and 50 m/min on the Y and Z axes, ensuring rapid and efficient material handling.

- Applications: Ideal for process profiles, including aluminum and PVC, as well as light alloys and steel.

Why Choose the Rumba?

- Efficiency: Capable of enabling machining operations on complex profiles, it reduces lead times and maximizes output.

- Versatility: Suitable for process aluminum profiles, PVC extrusions, and steel components, making it a valuable asset for diverse industries.

- Modern Design: Fully compatible with Industry 4.0 standards, including Wi-Fi connectivity and remote monitoring for real-time operational control.

Optional Features

Customize your Rumba to fit specific business needs with these optional features:

- Upgraded 6.6 kW electrospindle for heavy-duty applications.

- Additional clamps for enhanced material handling.

- Micro-drop lubrication system for tool longevity and better surface finishes.

- Advanced software licenses for CAM and CAD integration, including HICAM 3 ADVANCE and CADXTRACT 3D file detection.

- UL-CSA standards compliance for North American operations.

A Comprehensive Solution for Modern Machining

The Rumba stands out as a 4-axis CNC machining center that combines precision, speed, and versatility. It’s designed to process aluminum profiles, steel, PVC, and light alloys efficiently, making it indispensable for businesses aiming to enhance productivity and output quality.

From performing drilling to end milling and other complex machining tasks, the Rumba ensures precision, reliability, and ease of use. With its advanced features and robust build, this machine is an investment in efficiency and performance.