Gemma

VECTRA L

VECTRA L

Couldn't load pickup availability

Hydropneumatic crimping machine for joining corners suitable for all ranges of aluminum profiles.

Maximum caulking height: 150mm

Press force 3,5 t (35 kN)

Don't need this powerful? Check out the Vectra with 3kN or crimping force for profiles max 120 x 120 mm.

Share

Vectra L Hydraulic Crimping Machine for Aluminum Profiles

Product Overview

The Vectra L Hydraulic Crimping Machine, developed by Gemma Group, is the ultimate solution for precise and efficient corner crimping of aluminum profiles. Equipped with crimping knives for precise corner joining, this machine is engineered to meet the demands of modern manufacturing while ensuring ease of operation and adherence to safety standards.

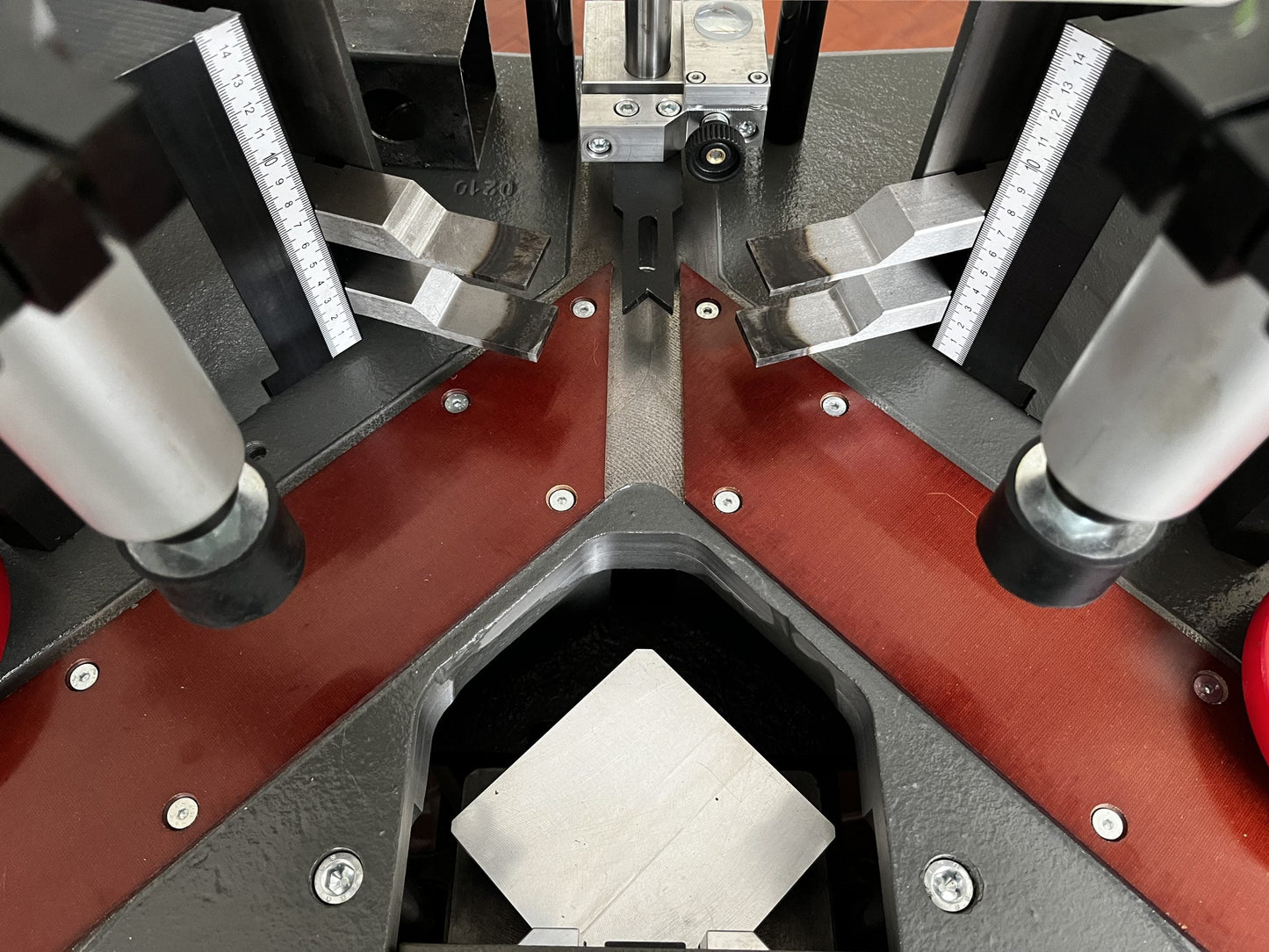

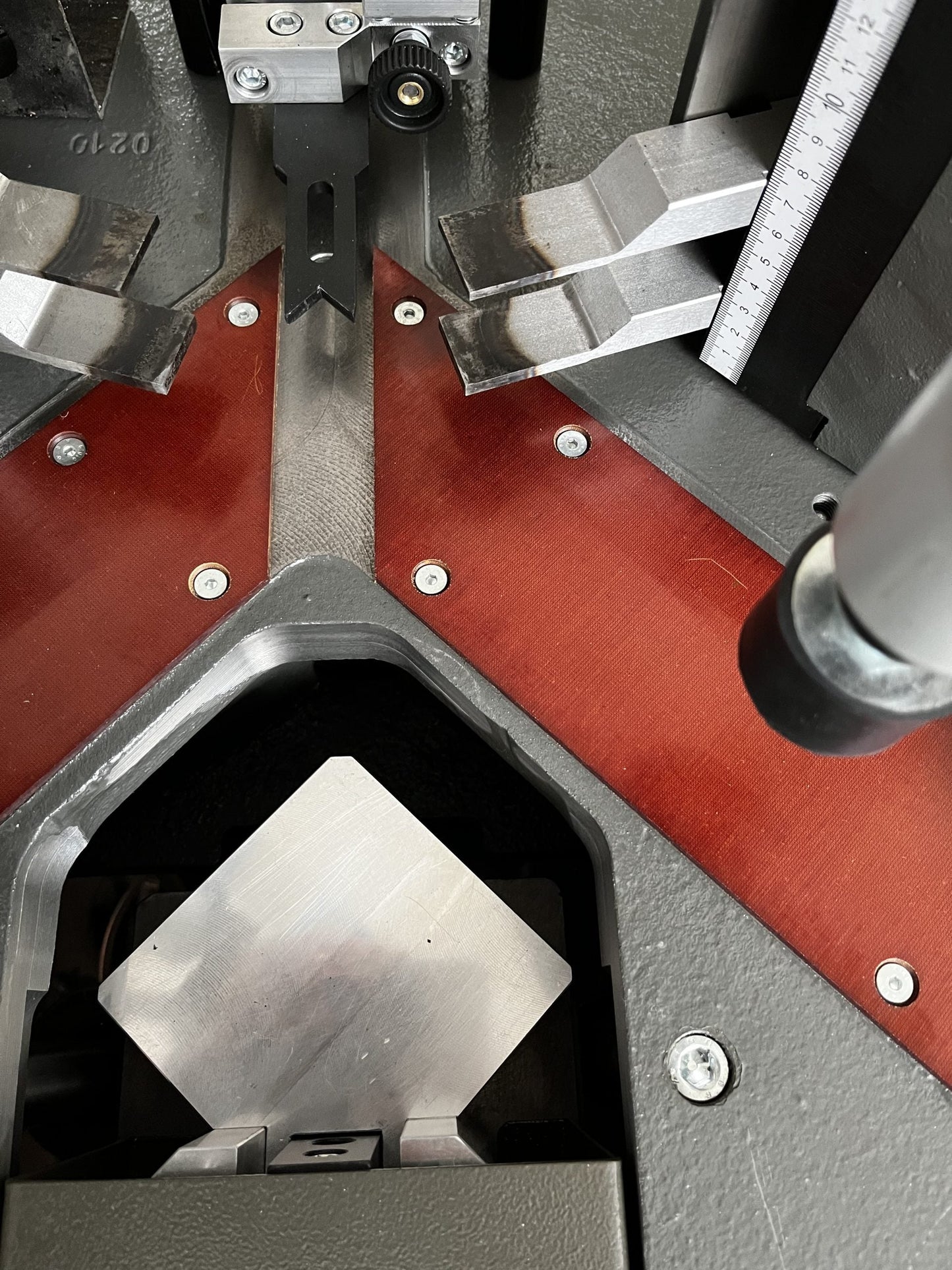

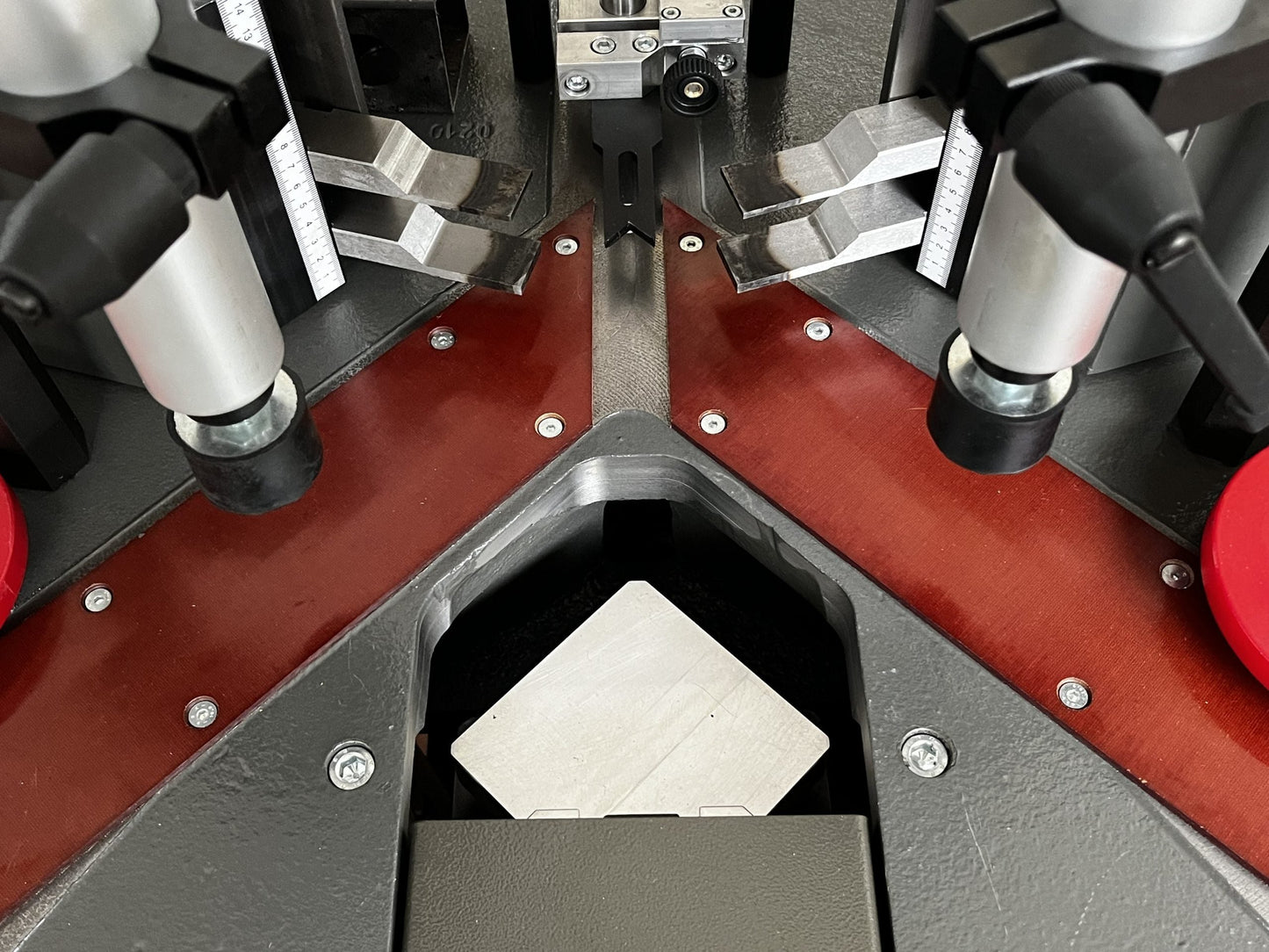

The Vectra L Hydraulic Corner Crimping Machine is a high-performance solution designed for precise 90-degree corner joining of aluminum profiles. This advanced machine is equipped with a powerful hydraulic system capable of delivering a maximum pressing force of 3500 kg (7,700 lbs), making it ideal for heavy-duty applications. The combination of a hydraulic crimping system and a pneumatic clamping system ensures that aluminum profiles are crimped with exceptional precision and efficiency. Whether you are working on large-scale industrial projects or intricate manufacturing tasks, it stands out as a reliable and robust corner crimping machine.

Key Features of Hydraulic Corner Crimping Machine

- Powerful Hydraulic System Equipped with a maximum pressing force of up to 3.5 tons, the Vectra ensures robust crimping performance suitable for a variety of aluminum profile applications. The powerful hydraulic system includes hydraulic pistons for enhanced strength and precision.

- Versatile Pneumatic Clamping System Two horizontal pneumatic clamps offer secure profile positioning, enhancing stability and accuracy during the crimping process.

- Crimping Tools for Customization The machine comes with a kit of three pressing knives (3 mm, 5 mm, 7 mm), providing flexibility for different profile sizes and designs.

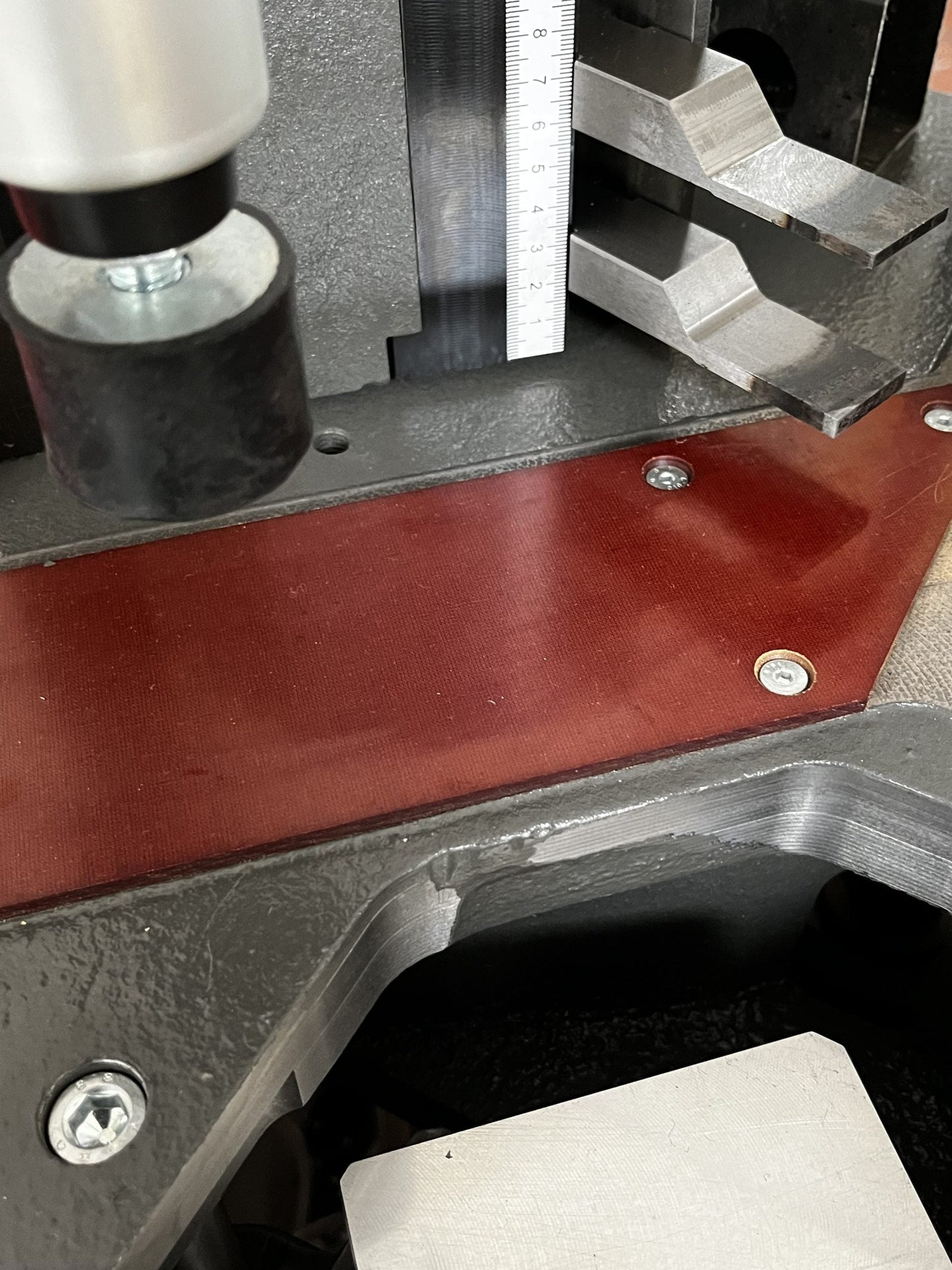

- Adjustable Work Area With a crimping height of 150 mm and a blade working stroke of 12 mm, the Vectra L can handle diverse profile dimensions and shapes.

- Precision Through Automatic CenteringThe graduated ruler with reference stops ensures precise alignment and correct assembly, minimizing errors during production.

- User-Friendly Design A foot pedal allows for hands-free operation, while the eccentric leaner ensures ergonomic use, enhancing productivity.

- Safety Compliance Fully compliant with CE safety regulations, the Vectra L includes cutting-area protections to safeguard operators.

Technical Specifications

- Power Supply: Compressed air at 7 Bar

- Air Consumption: 35 Nl per cycle

- Maximum Crimping Height: 120/150 mm

- Blade Working Stroke: 10.5/12 mm

- Dimensions: 950 x 800 x 1150 mm

- Weight: 440 kg

Benefits and Advantages

This Hydraulic Corner Crimping Machine offers a multitude of benefits and advantages that make it a standout choice for professionals in the industry. Its high precision and accuracy in corner crimping and assembly ensure that every project meets the highest standards. The powerful hydraulic system is designed for heavy-duty applications, providing the strength needed for demanding tasks. The pneumatic clamping system enhances efficiency by securely holding profiles in place, while the automatic centering feature ensures precise alignment every time. The adjustable crimping tool movement allows for customized crimping, catering to various profile sizes and designs. Additionally, the foot pedal operation facilitates easy and convenient profile pressing, boosting productivity. Built with durable and long-lasting materials, the APIS-06 H promises extended machine life, making it a valuable investment for any manufacturing setup.

Safety and Maintenance

Safety and maintenance are paramount in the design of the Vectra Hydraulic Corner Crimping Machine. The machine features a pneumatically operated profile centering set square and an eccentric leaner for automatic centering of profiles, significantly reducing the risk of accidents and injuries. The powerful hydraulic system, with a maximum hydraulic pressure of 100 bar, ensures safe and efficient operation. Maintenance is straightforward and user-friendly, with easily accessible components that simplify regular upkeep. The machine’s CE certification underscores its compliance with international safety standards, providing peace of mind to operators and ensuring a safe working environment.

Why Choose Vectra?

- Efficient Operation: Hydraulically crimping profiles ensures faster cycle times without compromising on quality.

- Precision Engineering: The millimeter-scaled adjustments and robust design guarantee a seamless manufacturing process.

- Safety First: Adhering to CSA safety directives, the Vectra prioritizes operator protection.

Applications for Aluminium Profiles

The Vectra is perfect for industries requiring precise corner crimping of aluminium profiles, including window and door manufacturing, furniture assembly, and industrial construction.